Course Description

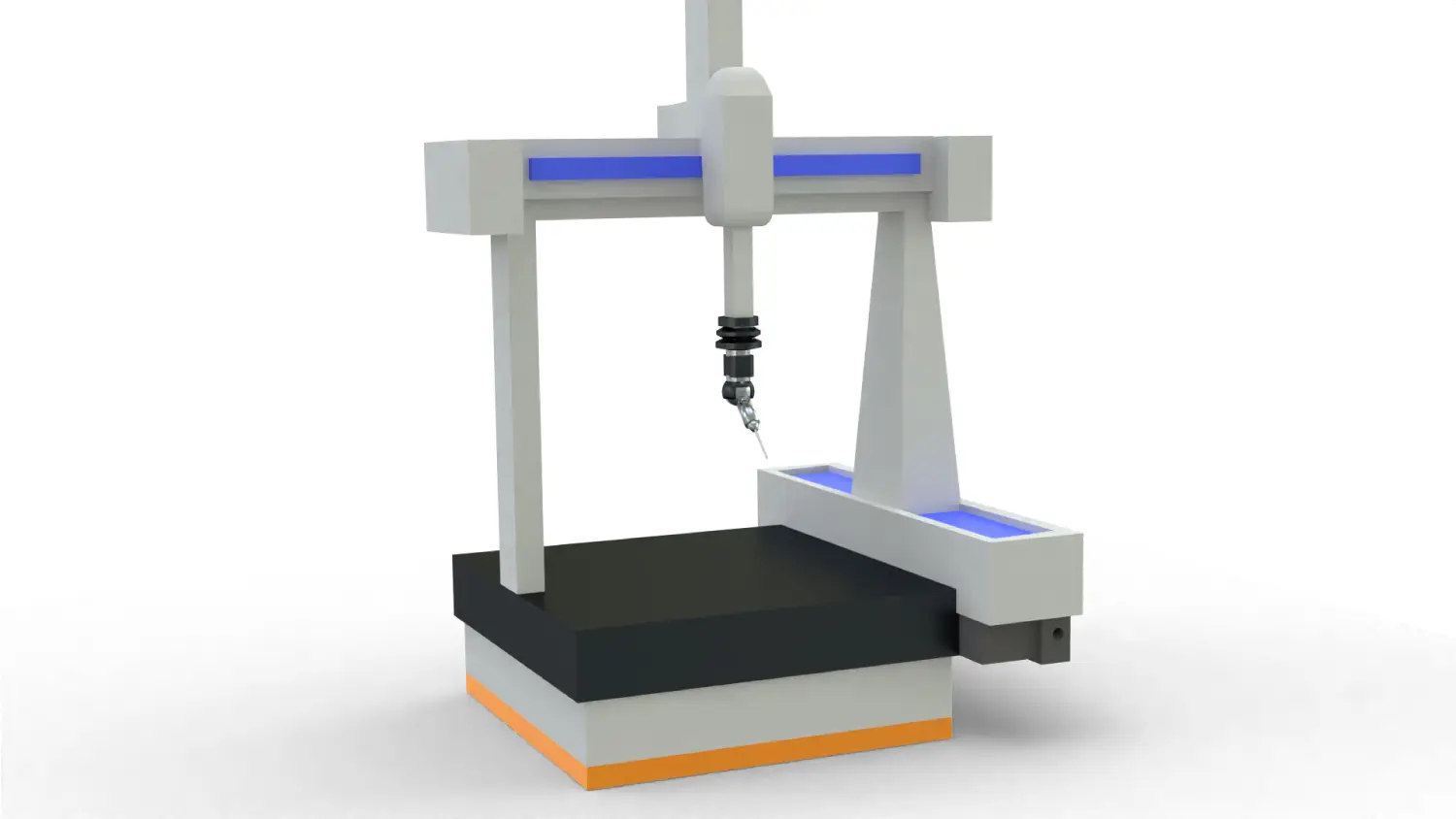

Inspection is a key factor for a part’s success. A Coordinate Measuring Machine (CMM), being fully automated, enhances the inspection methodology by enabling quick and precise measurements. The THORS Coordinate Measuring Machine (CMM) Basics course illustrates the indispensable role of the CMM in the measurement world. Packed with graphics, the course will leave the learner with a valuable learning experience about the types of CMMs and the components of a CMM, as well as the measurement and reporting process of a CMM.

Who will benefit from this CMM course?

Anyone operating a CMM machine including CMM Operators, Quality Engineers, Quality Managers, Design Engineers, and Manufacturing Engineers

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Coordinate Measuring Machine (CMM) Basics

*upon successful completion

Related Posts

Developing Soft Skills in the Tech Industry

Soft skills in the tech industry, where precision and expertise are paramount, might seem secondary. However, soft skills such as communication, teamwork, and problem-solving, play

The Role of Virtual Reality in Technical Training

In the rapidly evolving landscape of technology and industry, virtual reality (VR) in technical training is leading a revolutionary transformation in how professionals are trained.

5 Reasons Why a Culture of Learning can Lead to Success

Learning is continuous. After all, there are always new skills to learn and techniques to adopt. A culture of learning in an organization can also