Course Description

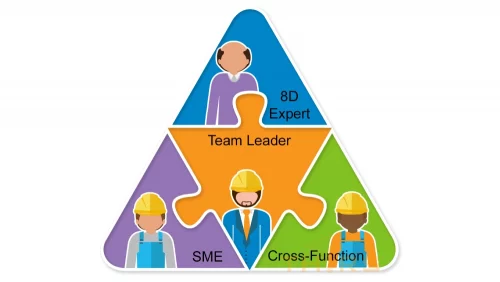

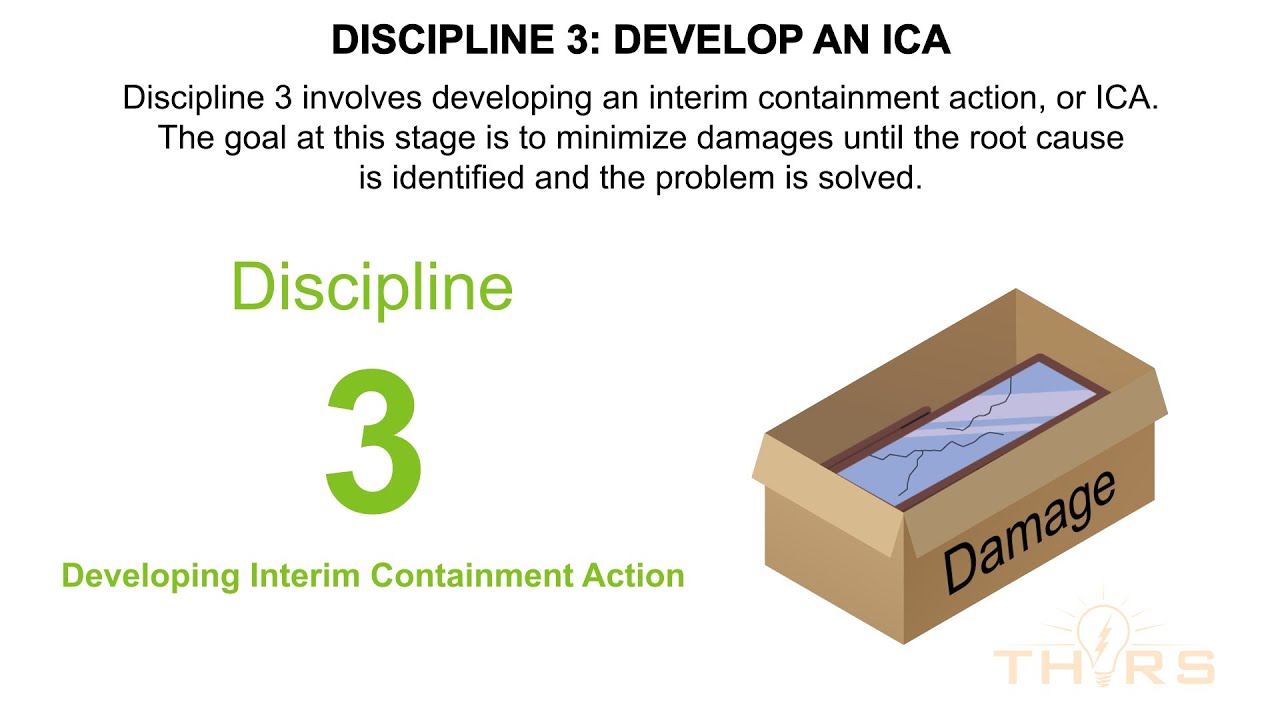

8D Problem-Solving Basics introduces learners to the popular “8 Disciplines,” commonly referred to as 8D. The 8D problem-solving methodology is an important quality tool utilized in a variety of industries. Presented in THORS’ highly visual and interactive learning format, this course will help employees become familiar with the important terminology and methodology associated with 8D implementation.

Who will benefit from this 8D Problem-Solving course?

Any individual, team, or organization involved in quality assurance processes. Though the examples in this course pertain to the manufacturing industry, the problem-solving methodology is universal, and can apply to anyone who seeks to approach problem solving with a scientific, systematic, proven methodology.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for 8D Problem-Solving Basics

*upon successful completion

Related Posts

Training Perspective: Looking Back to Look Ahead

Companies are constantly reviewing ways to reduce costs and keep positive margins. During times of economic recession, external pressures from competitors as well as internal pressures

5 Reasons Why a Culture of Learning can Lead to Success

Learning is continuous. After all, there are always new skills to learn and techniques to adopt. A culture of learning in an organization can also

Certificate Programs vs Completion Certificates

Certificate programs and completion certificates are both types of educational programs that can provide valuable training and skills to individuals in a variety of fields.