Course Description

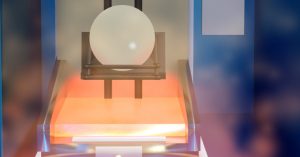

Semiconductor manufacturing involves complex processes and multiple techniques. The THORS Semiconductor Manufacturing III course explores several crucial processes, including etching, ion implantation, and thermal processing. It provides information on different etching and cleaning techniques for etching diverse materials. The course also covers the ion implantation process, various types of implanters, and thermal processing. Interactive quizzes are incorporated into the course to enhance the learning journey, enabling learners to assess their comprehension and retention of visually stimulating content.

Who will benefit from this semiconductor manufacturing process course?

Quality, manufacturing, engineering, design, testing, purchasing, and sales functions at organizations that require an understanding of how semiconductor devices are manufactured.

Certificate Awarded for Semiconductor Manufacturing III

*upon successful completion

Related Posts

Developing Soft Skills in the Tech Industry

Soft skills in the tech industry, where precision and expertise are paramount, might seem secondary. However, soft skills such as communication, teamwork, and problem-solving, play

How THORS Courses Helped a Mechatronics Student in Germany

Sasshank is an international student attending University in Germany where he studies mechatronics engineering. He was born in Tamil Nadu, where he attended various schools

Women in Manufacturing: An Interview with Kavita Krishnamurthy

As part of a tribute to women in manufacturing, we at THORS eLearning Solutions decided to showcase one of our own, Kavita Krishnamurthy. Kavita is