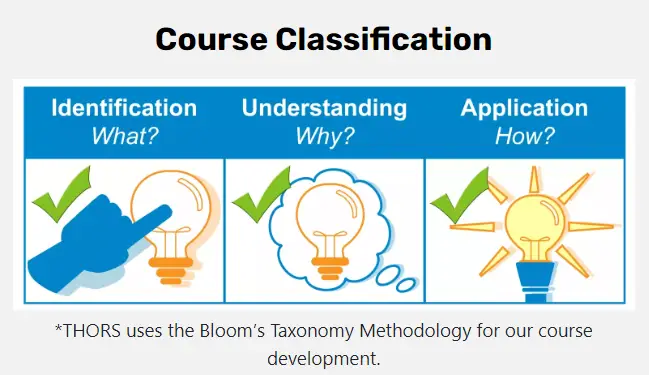

Course Description

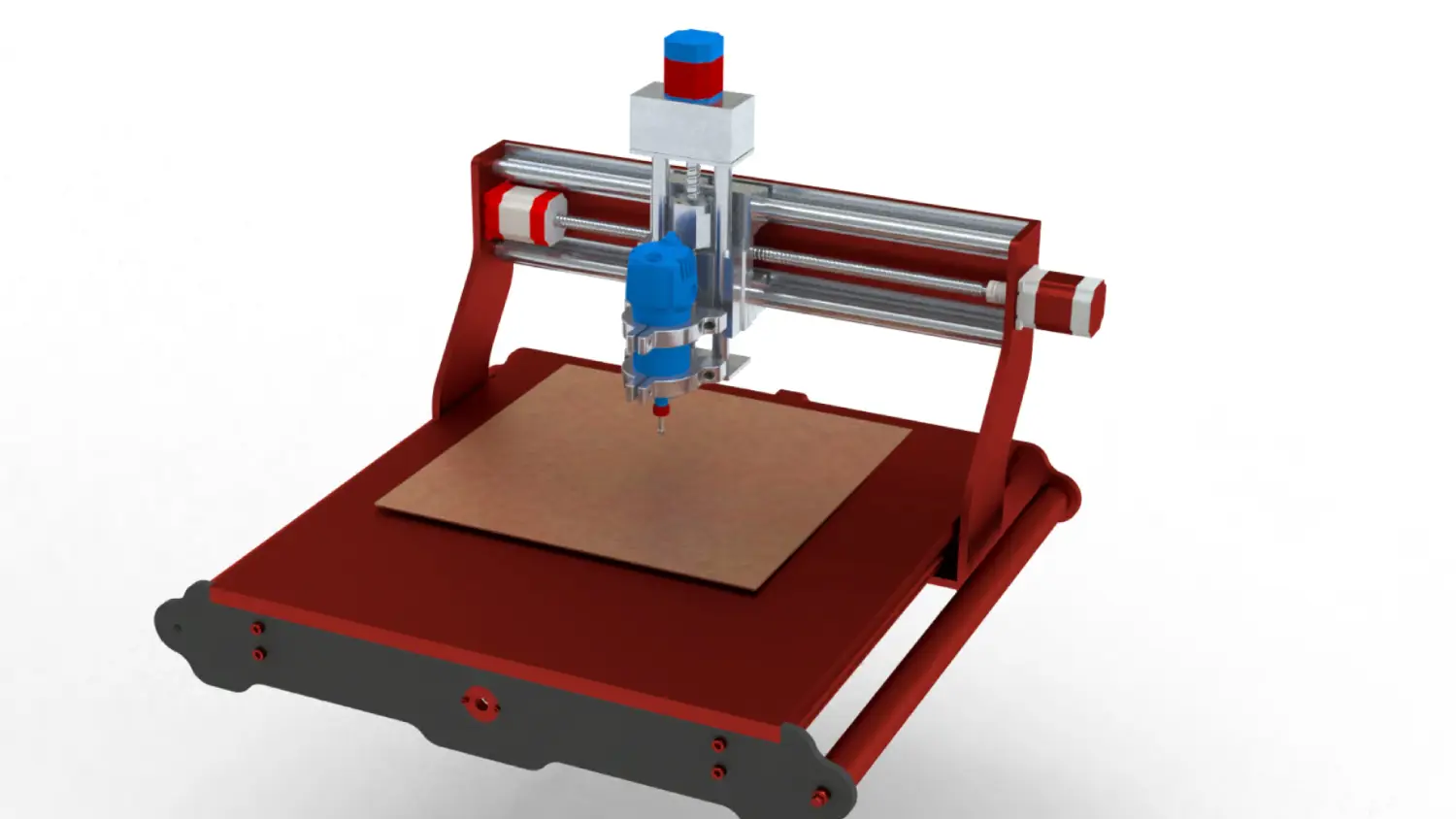

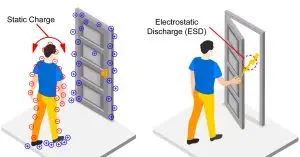

The THORS Printed Circuit Board (PCB) Manufacturing course introduces the learner to the PCB manufacturing processes, starting from laminate manufacturing and PCB designing. The course covers common manufacturing processes, such as the patterning process, multilayer PCB manufacturing processes, solder mask application, silkscreen application, and surface finish, followed in the industry. Presented in THORS’ highly visual and interactive learning format, this course will equip learners to broaden their knowledge of PCB manufacturing and its related technologies.

Who will benefit from this printed circuit board (PCB) manufacturing course?

Quality, manufacturing, engineering, design, testing, purchasing, and sales functions at organizations that require an understanding of the PCB manufacturing processes.

Certificate Awarded for Printed Circuit Board (PCB) Manufacturing

*upon successful completion

Related Posts

Upskilling in the Manufacturing Industry with THORS

In today’s rapidly evolving manufacturing industry, staying up to date with the latest technologies and processes is crucial to remaining competitive. Upskilling in the manufacturing industry

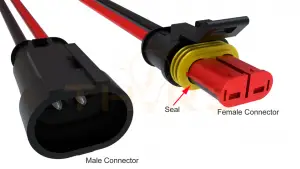

Top 5 Applications of Sealed Connectors in Wiring Harnesses

Sealed connectors in a wiring harness are protective components designed to prevent environmental contaminants such as water, dust, and chemicals from compromising electrical connections. The

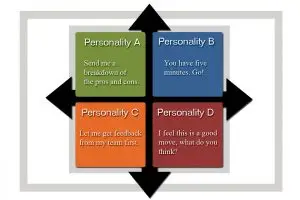

Knowing Customer’s Personality Style Adds Value

Maybe you think the value is obvious. If you can speak the same “language” as the person you are talking with, you can build trust