Course Description

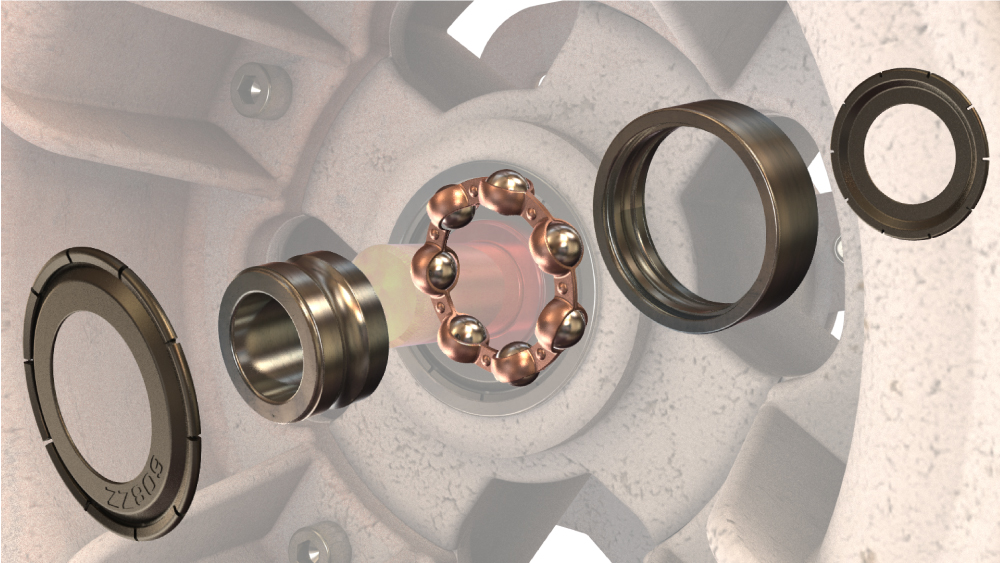

Bearing Fundamentals introduces learners to the basic components, considerations, and types of bearings used in the industry. In this course, there are multiple ways in which the fundamentals of bearings are presented such as with 3D animations, 3D/2D models, and GIFs. This course contains material which is suitable for those new to bearings and those who have experience in the industry.

Who will benefit from this Bearings course?

Equipment Designers; Equipment Maintenance Professionals; Engineering Students.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Bearing Fundamentals

*upon successful completion

Related Posts

Women in Manufacturing: An Interview with Kavita Krishnamurthy

As part of a tribute to women in manufacturing, we at THORS eLearning Solutions decided to showcase one of our own, Kavita Krishnamurthy. Kavita is

Training Perspective: Looking Back to Look Ahead

Companies are constantly reviewing ways to reduce costs and keep positive margins. During times of economic recession, external pressures from competitors as well as internal pressures

Why Digital Assessment Tools for Hiring are Essential

Hiring the right person for a technical position is crucial for the success of any organization. However, what happens when a new hire lacks the