Course Description

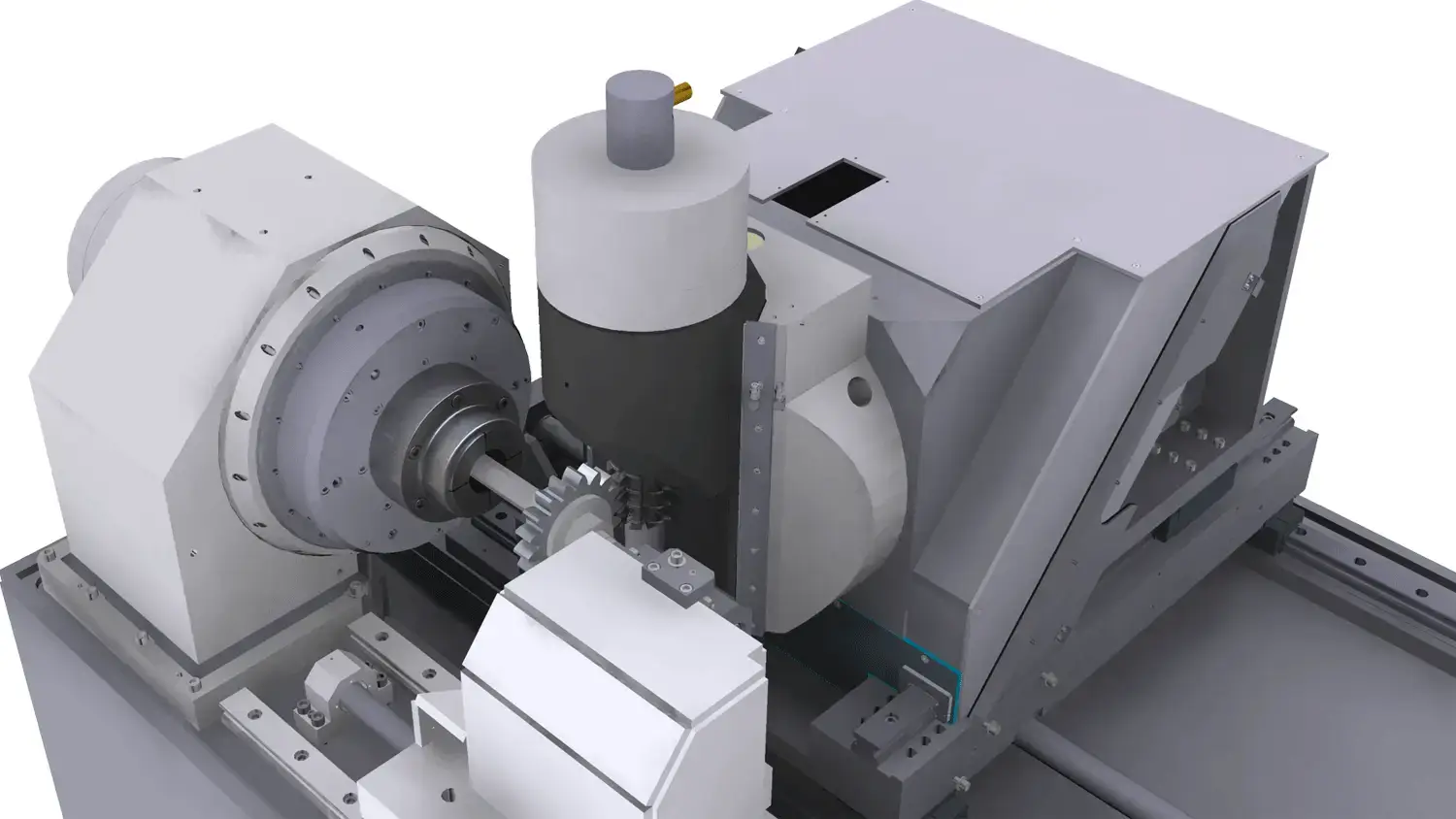

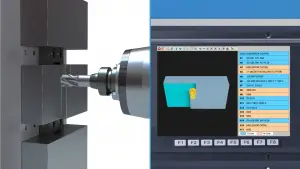

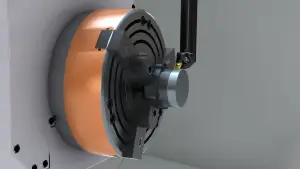

The Gear Hobbing Video Series 1 course introduces learners to the basic functions, components, and terminology associated with modern gear hobbing machines. The series also addresses the axis coordinate system applied to hobbing, the required hobbing tools such as hobs and arbors, and the workholding devices commonly used for the process.

Who will benefit from this Gear Hobbing video series?

Operators, Inspectors, Sales, and Purchasing.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Gear Hobbing Video Series 1

*upon successful completion

Related Posts

Entertainment in Education is the Future

Prepare to embark on an extraordinary adventure as we dive into the captivating world of the future of education. We will unravel the seamless integration

The Role of Virtual Reality in Technical Training

In the rapidly evolving landscape of technology and industry, virtual reality (VR) in technical training is leading a revolutionary transformation in how professionals are trained.

Cross-Cultural Training Benefits

Understanding Cross-Cultural Training In today’s interconnected world, businesses are expanding beyond borders. To thrive globally, organizations must equip their employees with cross-cultural skills. Cross-cultural training