Course Description

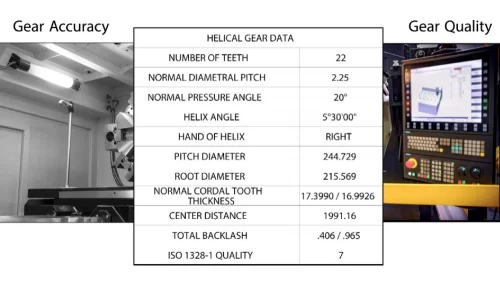

Gear Chart Interpretation: Elemental Measurements on Cylindrical Gears introduces learners to the latest ISO global gear accuracy standard, the factors that define gear accuracy, and the evaluation of measured deviations against the allowable deviations on a gear inspection report, or “gear chart”. In this course, learners engage with animations and interactives demonstrating the analytical quality inspection processes performed to obtain the values classified as elemental measurements according to the global standard.

Who will benefit from this Gear Inspection Reports course?

Any learner, such as a beginning engineer, who must be familiar with reading and interpreting gear charts generated for spur and helical gears.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Gear Chart Interpretation: Elemental Measurements on Cylindrical Gears

*upon successful completion

Related Posts

Spur Gears versus Helical Gears

Gear types can be classified according to the relative position of their axes of revolution. For example, there are gears for parallel shafts, gears for intersecting

Training Programs are Critical to Attracting and Retaining Talent

In today’s rapidly changing business landscape, organizations face a unique set of challenges in finding, hiring, and retaining top talent. The tight labor market has

Examining Gear Hobbing Equipment and Tools

What is gear hobbing? Gear hobbing is considered a generating process and is the most common method of producing teeth in gears of all sizes.