In injection molding, every second of cycle time directly impacts profitability. Strategic mold design decisions can reduce cycle times by 20-40%, translating to significant production gains and cost savings. While multiple factors influence production efficiency, mold design stands out as the most critical element in manufacturing success.

Cycle time is made of four phases: injection, packing or holding, cooling, and ejection. The cooling phase typically accounts for the maximum of total cycle time, making it the primary target for optimization. During cooling, molten plastic solidifies from processing temperature to ejection temperature, following fundamental heat transfer principles that mold designers can influence through strategic design choices. In this blog, we will review this and other strategies that can optimize cycle time and production.

Cooling System Design

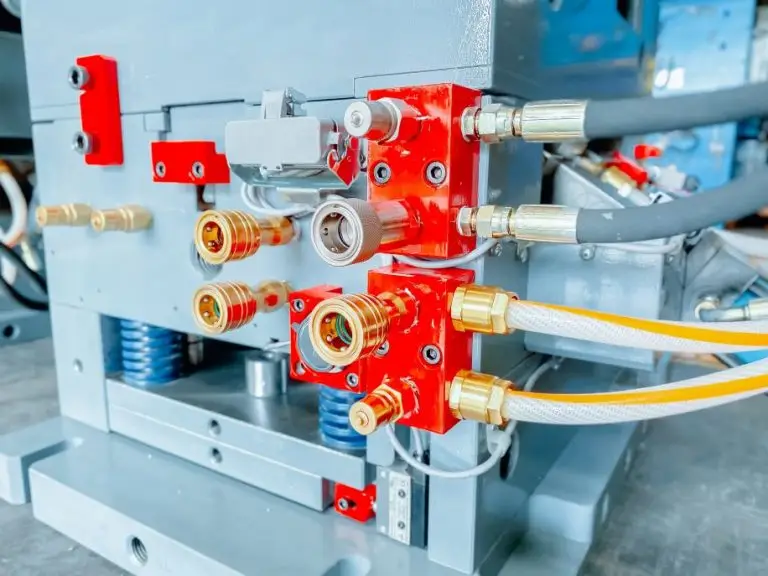

The cooling system represents the most influential aspect of mold design for cycle time reduction. Effective cooling requires the strategic placement of cooling channels to ensure uniform heat extraction throughout the part. Proper cooling channel diameter, spacing, and coolant flow rate all contribute to heat transfer efficiency, requiring designers to balance cooling effectiveness against manufacturing costs.

Advanced cooling technologies include 3D printed conformal channels beryllium copper inserts for high-heat areas, and heat pipes for difficult-to-cool sections. While these technologies carry higher initial costs, they often justify investment through optimized cycle times and part quality over the lifetime of the mold.

Gate Design and Placement

Gate design significantly influences fill time and cooling efficiency. Proper gate sizing ensures adequate flow while minimizing injection pressure requirements. Oversized gates extend cooling time due to thicker sections, while undersized gates create excessive shear heating and longer fill times.

Gate location affects flow balance and cooling uniformity. Centrally located gates typically provide optimal flow patterns and balanced cooling, while off-center gates may create hot spots that extend cooling time. Multiple gates can reduce fill time but require careful balancing to avoid cooling complications.

Runner System Configuration

Runner system design impacts injection time, material usage, and cooling requirements. Hot runner systems eliminate the need to cool runner material, potentially reducing cycle time by 10-30% compared to cold runner systems.

Cold runner designs require careful attention to sizing and geometry to minimize cooling time while ensuring adequate flow. Balanced runner systems ensure simultaneous cavity filling, preventing premature cooling in some cavities while others are being filled.

Part Wall Thickness

Part wall thickness critically affects cooling time, as cooling time increases exponentially with thickness. Even small thickness reductions yield significant cycle time improvements. Uniform wall thickness promotes even cooling and prevents hot spots that extend cycle time, while varying thickness creates cooling imbalances that force the entire cycle to wait for thickest sections to solidify.

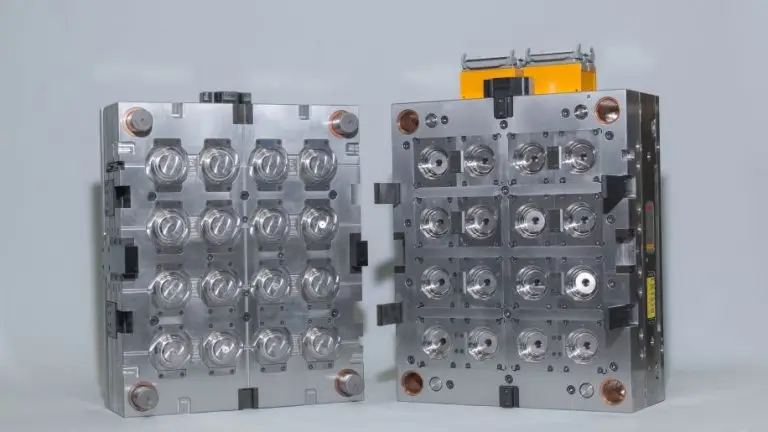

Multi-Cavity Considerations

Multi-cavity molds offer dramatic production efficiency improvements by producing multiple parts per cycle. However, optimal performance requires careful attention to flow balance, cooling uniformity, and ejection timing.

Balanced filling ensures all cavities fill simultaneously, preventing premature cooling in some areas. This requires precise runner design and proper gate sizing. Cooling balance becomes more challenging with multiple cavities, as temperature variations can force longer cycle times to ensure adequate cooling in all locations.

The optimal number of cavities balances increased output per cycle against potential cycle time increases due to cooling and ejection challenges. This balance depends on part geometry, material properties, and production requirements.

Material Impact

Different materials exhibit varying thermal properties that significantly impact cooling requirements. High-temperature materials like PEEK require longer cooling times but may benefit more from enhanced cooling system design than commodity plastics.

Crystalline materials such as polypropylene require controlled cooling rates for optimal crystallization, potentially limiting aggressive cooling strategies. Filled materials, particularly glass-filled grades, often exhibit improved thermal conductivity that can reduce cooling time while requiring modified designs for increased wear resistance.

Balance of Quality and Speed

Optimizing for minimum cycle time must balance against part quality requirements and long-term production stability. Aggressive cycle time reduction can lead to part defects, increased reject rates, or mold wear that ultimately reduces overall efficiency.

Process windows define acceptable cycle time ranges that produce quality parts consistently. Mold design should maximize this process window, providing flexibility for optimization while maintaining quality standards. Statistical process control helps identify optimal balance points between cycle time and quality for specific applications.

Economic Considerations

Cycle time improvements must be evaluated against implementation costs. A 10% cycle time reduction might justify significant mold design investments for high-volume production but may not be economical for low-volume applications.

Return on investment calculations should consider total production volume over the lifetime of the mold, the impact of piece prices, and potential quality improvements. Energy savings from shorter cycles and reduced cooling requirements also contribute to economic justification.

Future Trends and Technologies

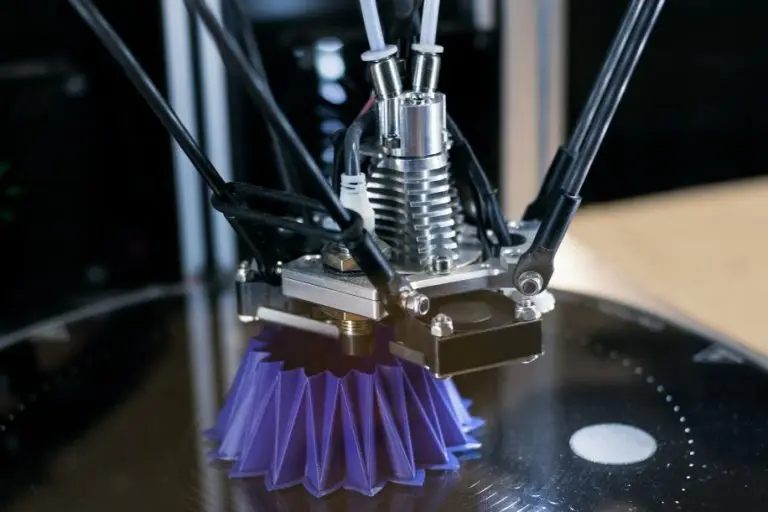

Additive manufacturing is revolutionizing mold design possibilities, particularly for cooling optimization. 3D printed mold inserts enable complex cooling geometries previously impossible to manufacture, opening new cycle time reduction possibilities.

Advanced simulation tools predict and optimize cycle times during design phases rather than through expensive trial-and-error approaches. Industry 4.0 technologies, including IoT sensors and machine learning algorithms, enable continuous optimization and prevent efficiency-reducing failures.

Implementation of Smart Systems

Successful cycle time optimization requires a holistic approach considering all molding cycle aspects and their interactions. While cooling system optimization offers the greatest potential for reduction, the best results come from coordinated improvements across all design elements.

Smart mold designs with integrated sensors enable real-time monitoring of temperature, pressure, and part quality, facilitating automatic cycle optimization and early issue detection. These systems represent the future of efficient production, automatically adjusting parameters based on measured conditions.

Conclusion

Mold design represents one of the most powerful tools for improving injection molding cycle time and production efficiency. Through strategic cooling systems, optimized gate placement, balanced runner configuration, and careful part geometry considerations, designers can achieve significant improvements in production throughput and cost-effectiveness.

Success requires balancing multiple factors, including cooling efficiency, flow dynamics, part quality, and economic considerations. As manufacturing becomes increasingly competitive and sustainability drives efficiency requirements, optimized mold design becomes even more critical for success.

The future lies in smart, data-driven mold designs that automatically optimize performance while maintaining quality standards. Companies investing in advanced mold design capabilities and continuous improvement processes will achieve significant competitive advantages through superior production efficiency.

Read a related blog: 8 Common Injection Mold Design Mistakes and Tips to Avoid Them

Learn more in the THORS course, Injection Molding Design Fundamentals.