Course Description

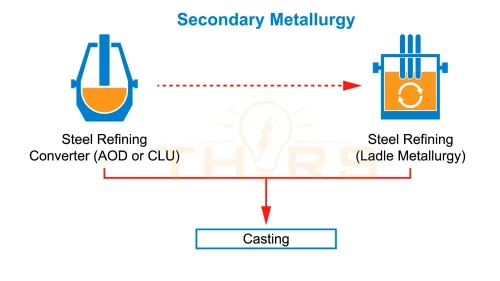

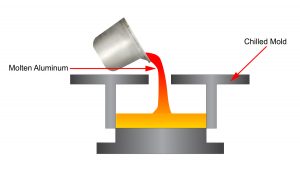

Steel Basics introduces learners to the basic equipment, terminology, and processing steps associated with modern steelmaking operations. As a combination of metallic and non-metallic elements, steel is considered versatile, adaptable, and available for manufacturing in large quantities. Understanding the basic principles of the steelmaking process is crucial for anyone involved in this diverse industry. This course will focus on the steel basics such as basic steelmaking processes, the mechanical properties of steel, and steel grades.

Who will benefit from this Steelmaking course?

Companies, individuals, or educational institutions that require an understanding of the basic equipment, terminology, and processing steps associated with modern steelmaking operations.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Steel Basics

*upon successful completion

Related Posts

Orientation versus Onboarding: Understanding the Differences

When discussing “orientation versus onboarding”, it’s vital to recognize that, though frequently conflated, they serve distinct purposes in the professional environment. Despite both focusing on

The Ever-Expanding Steel Tubing Market: A Peek into the Future

How have steel tubes performed in the past? The oil and gas industry is the major consumer of steel tubes, accounting for half of the

The Essential Skills of Modern Purchasing Professionals

In my professional career that spans more than three decades, I have had the privilege of working closely with purchasing. I can attest to the