Course Description

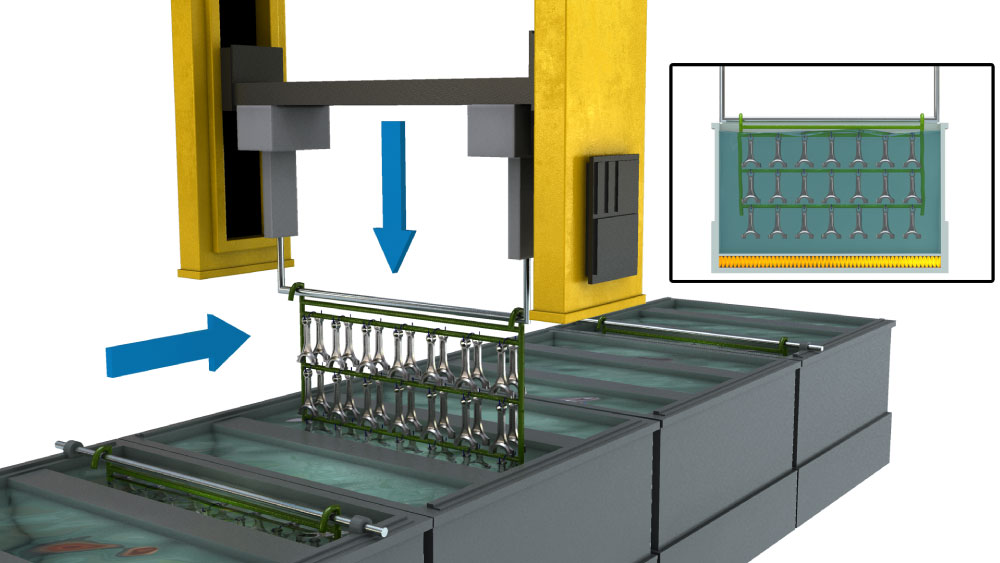

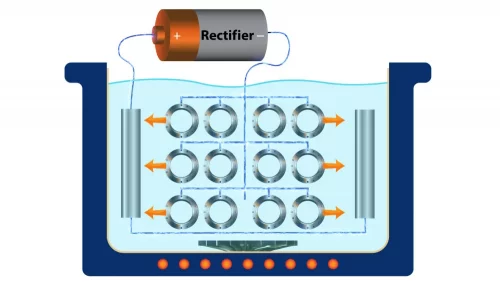

Plating Fundamentals introduces learners to the basic components, processes, and general terminology associated with metal plating industries. The information critical to metal plating is brought to life in this course using realistic 2D and 3D models, helpful animations, and interactive quizzes. The material in this course is beneficial for both those who are experienced and practiced in metal plating and related concepts, and those who are new to the field.

Who will benefit from this Metal Plating course?

Quality, manufacturing, engineering, designing, purchasing, and sales.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Plating Fundamentals

*upon successful completion

Related Posts

Training

Is Your Issue a Skills Gap or a Knowledge Gap?

You may have received a call to action to address the skills gap, which might feel making a bridge across the Grand Canyon with a

THORS Staff Writer

Training

Why Digital Assessment Tools for Hiring are Essential

Hiring the right person for a technical position is crucial for the success of any organization. However, what happens when a new hire lacks the

THORS Staff Writer

Training

Entertainment in Education is the Future

Prepare to embark on an extraordinary adventure as we dive into the captivating world of the future of education. We will unravel the seamless integration

THORS Staff Writer