Course Description

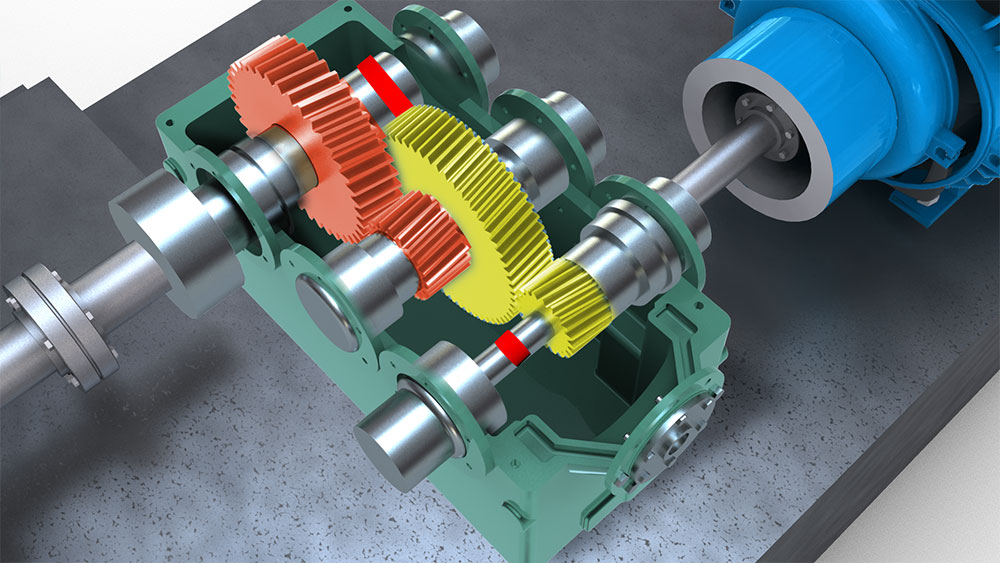

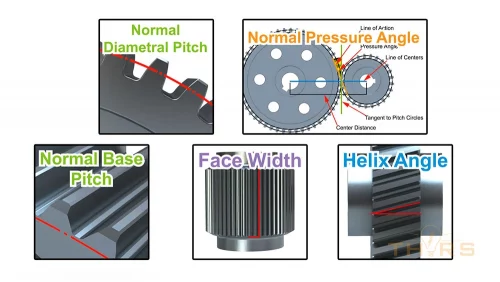

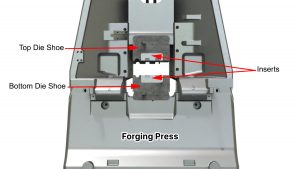

Gear design simplified! The THORS course, Spur and Helical Gear Design Fundamentals provides strategies for designing gears that meet given application requirements. This course, complemented with real-life examples, delves into the principles of selection and optimization of primary and secondary design variables.

Who will benefit from this Spur and Helical Gear Design course?

Design Engineers, Manufacturing Engineers, Operators, Inspectors, Sales, and Purchasing

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Spur and Helical Gear Design Fundamentals

*upon successful completion

Related Posts

How Can THORS Help Enhance Your College Education?

How Can THORS Help Enhance Your College Education? THORS Academy can help enhance your college education in a number of ways. Imagine being in a

5 Ways to Reduce Human Errors in Manufacturing

We cannot change the human condition, but in manufacturing we can certainly improve the way people work, where they work, and what systems they use.

Is Your Issue a Skills Gap or a Knowledge Gap?

You may have received a call to action to address the skills gap, which might feel making a bridge across the Grand Canyon with a