Course Description

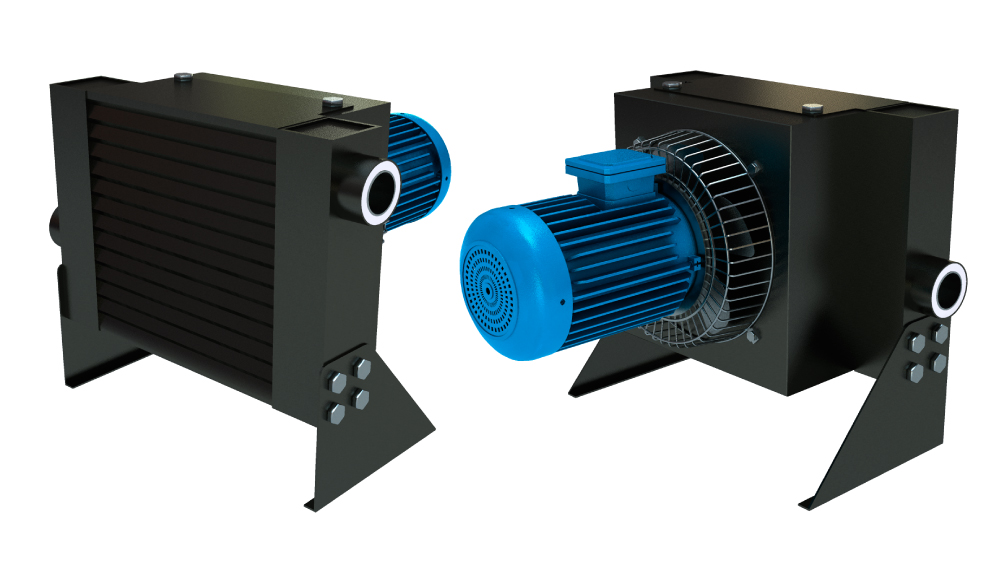

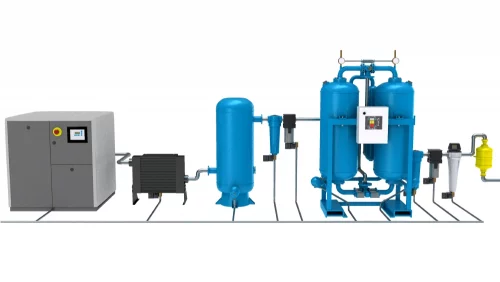

The Compressors: Ancillary Equipment course in an informative, intermediate-level overview to the ancillary equipment used to purify compressed air. In this course, learners are presented with the types of pollutants removed by the ancillary equipment during the purification stages, the lower-level purification equipment, the higher-level purification equipment, and the compressed air quality standards that drive ancillary equipment selection based on the end-use application of the compressed air. Learners who are compressed air system designers, compressed air system installers, and compressed air end users will find value in this course.

Who will benefit from this compressor air purification equipment course?

Any learner who must use or be familiar with the ancillary equipment used to purify compressed air, compressed air quality standards, and the stages of air purification.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Compressors: Ancillary Equipment

*upon successful completion

Related Posts

5 ways to reduce human errors in manufacturing

We cannot change the human condition, but in manufacturing we can certainly improve the way people work, where they work, and what systems they use.

5 signs you should invest in effective workforce training

In today’s constantly changing marketplace, the importance of workforce training has never been greater. Workforce training has the ability to not only increase workforce efficiency

Cross-Cultural Training Benefits

Understanding Cross-Cultural Training In today’s interconnected world, businesses are expanding beyond borders. To thrive globally, organizations must equip their employees with cross-cultural skills. Cross-cultural training