Due to the complex nature of the geometric dimensioning and tolerancing (GD&T) standard, a company’s bottom line profitability can be affected as a result of reading and interpreting errors. Users who have a lack of knowledge concerning the rules, symbols, conventions, and associated terminology of GD&T are more likely to make incorrect decisions.

One such area where a deficit in GD&T language fluency and comprehension can impact manufacturing is in the prototyping process. Situations where a limited understanding can affect this crucial process include the following:

Ineffective design:

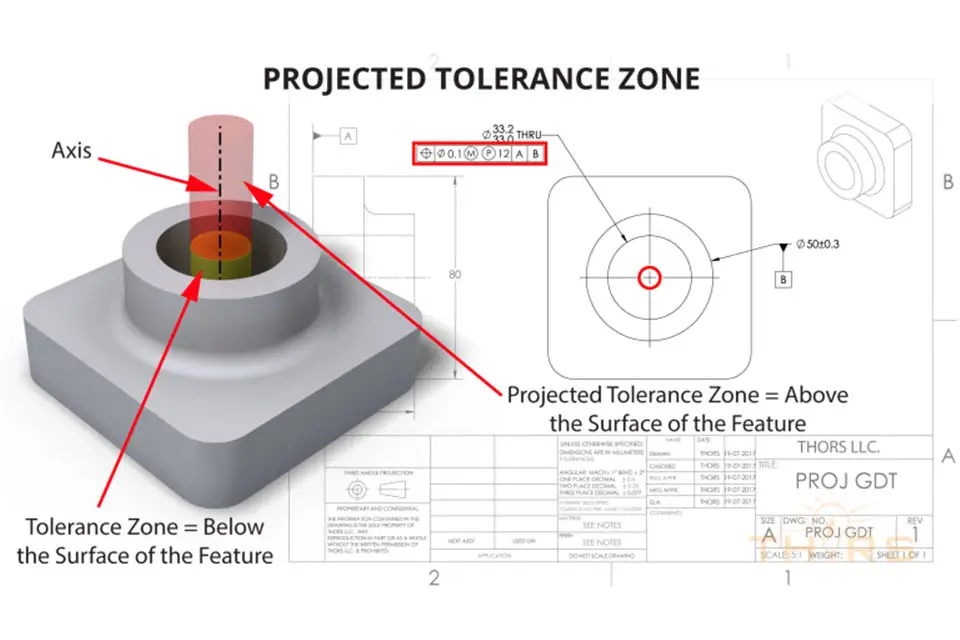

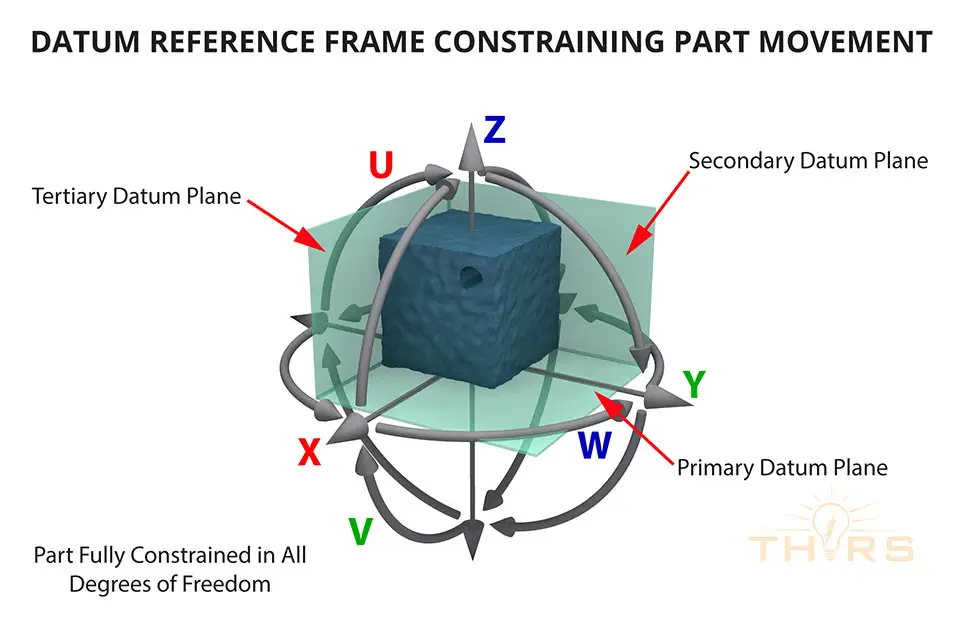

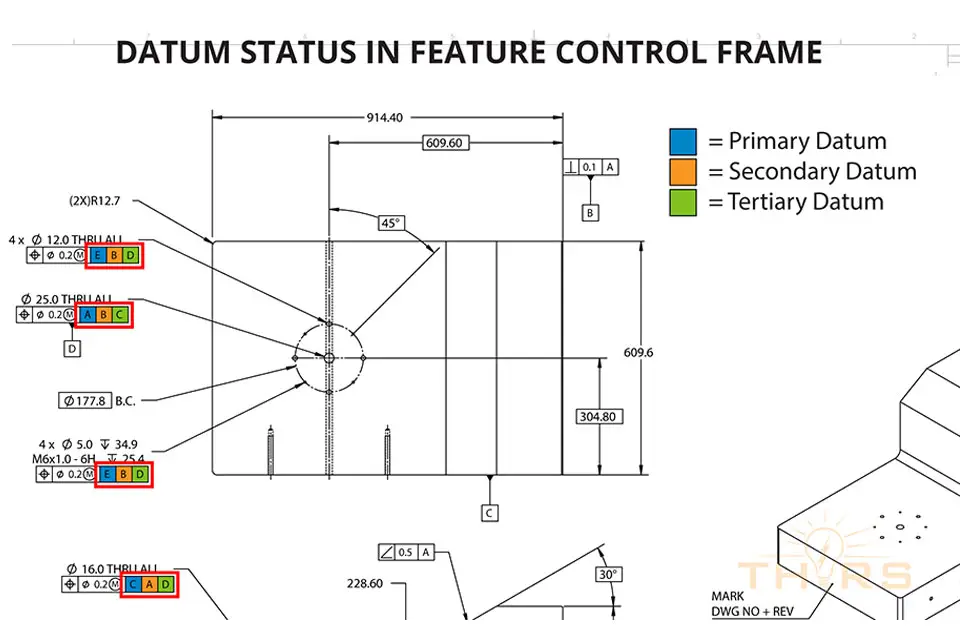

Designers who do not fully understand the concepts of GD&T may not include GD&T on a print where it would be beneficial. As a result, the part is now much more difficult to manufacture as required information, such as position tolerances, was not provided to ensure the part met fit, form, and function.

Inaccurate manufacturing:

Even when GD&T is effectively provided on a print, it may not be understood by the manufacturing team. As a result, there is a higher chance that the part will not be manufactured to the print’s requirements, thus impeding the assembly process. Inaccurate manufacturing means wasted materials, time, and money.

Increased timeline:

A limited understanding of GD&T in design, manufacture, or both can lead to multiple back and forth cycles in the prototyping process. With every additional cycle, the time it takes to bring the part into production increases, causing the prototyping timeline to grow longer. Longer timelines equal higher costs, which will ultimately affect bottom line profitability.

The inability to understand and interpret GD&T at any stage of development can have a huge effect on a company’s track to production. Therefore, it is essential for individuals within an organization’s design and manufacturing teams to all be well versed in the language of GD&T in order to have the greatest potential for success.

In the next installment of our GD&T series, we will discuss how an incomplete understanding of GD&T can impact product quality. We at THORS are also happy to announce that our GD&T Fundamentals course has launched!

Kavita Krishnamurthy is an ASQ certified Six Sigma Black Belt with over 15 years of experience in the field of process improvement, manufacturing engineering, and quality management in the automotive and gear industries. She is also the subject matter expert of our GD&T Fundamentals course.