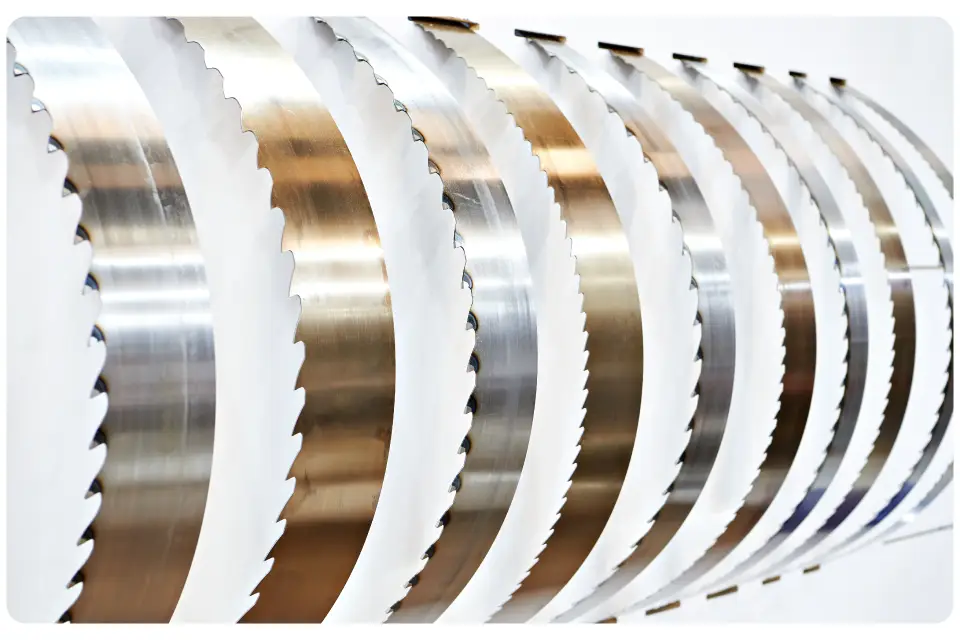

Modern band saw blades are in a constant state of improvement and refinement. The ever-growing demand for these efficient cutting tools is driving manufacturers to come up with innovations in the production of band saw blades. From materials to specialized treatments and technological advancements, band saw blades are undergoing a transformation to meet the evolving needs of various industries. Let’s delve into some of the advanced features of modern band saw blades.

The Emergence of Bimetal Blades

The birth of bimetal band saw blades was a significant advancement in the field of industrial band saw blades. Bimetal blades are made of two types of alloy steel, High Speed Steel (HSS) and spring steel. HSS is known for offering high strength, rigidity, and heat resistance, enabling sharp and smooth cuts at high speeds. Spring steel helps maintain the flexibility and strength of the blade. This combination offers the best of both worlds, resulting in an efficient performance. A study called Bimetallic Bandsaw Blade Market Size estimates the average annual growth rate of the bimetallic bandsaw blade market over the period from 2023 to 2030, indicating their superiority over monometallic blades.

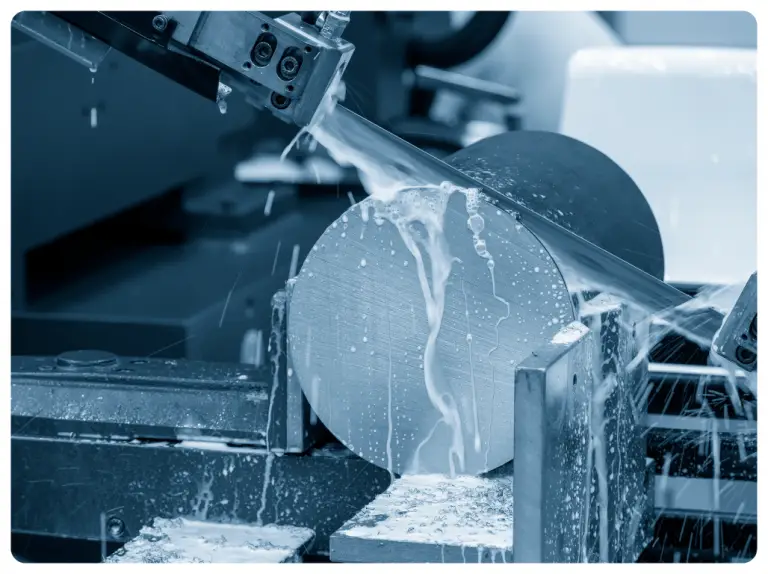

Treatments Aimed at Increasing Longevity

Ensuring durability is paramount when it comes to modern band saw blades. To meet this demand, manufacturers are turning to various surface treatments to extend the life of their blades. Among these treatments, cryogenic treatment has emerged as a popular choice. This process involves subjecting the blade to extremely cold temperatures following heat treatment processes. By undergoing cryogenic treatment, blades experience an increase in hardness and enhanced fatigue resistance. Additionally, blades treated with cryogenic processes boast high corrosion resistance, further enhancing their longevity and reliability in demanding cutting applications.

Coated Band Saw Blades

Coating band saw blades with specialized substances has become increasingly popular as a method aimed at enhancing performance, particularly in terms of heat resistance and overall efficiency. For instance, blades coated with diamond can cut through exceptionally hard and abrasive materials that would quickly dull traditional blades. Similarly, titanium aluminum nitride-coated blades are renowned for their remarkable hardness and wear resistance. As a result, coated band saw blades boast high durability, making them invaluable tools for tackling demanding cutting tasks across manufacturing industries.

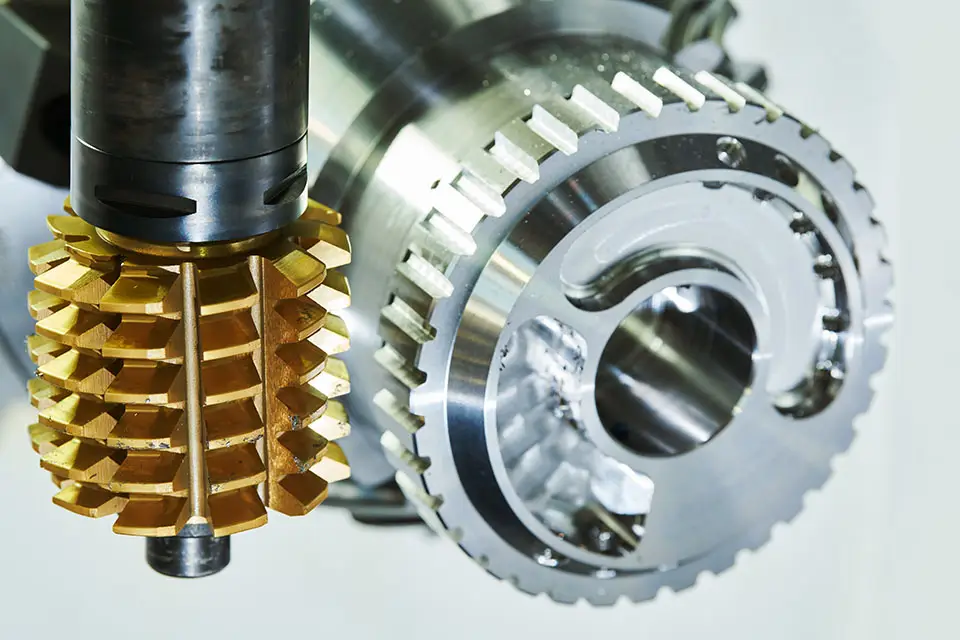

Blades Equipped with Special Inserts

Carbide-tipped blades are yet another specialization among the band saw blades. These blades are equipped with specially formulated carbon inserts at the teeth’s outer-most edge, offering superior cutting performance, particularly on hard metals.

Conclusion

Modern industrial band saw blades have come a long way to meet the increasing demands of efficiency, durability, and versatility in cutting operations. The emergence of blades, coupled with specialized treatments, coatings, and inserts, signals the prominent role played by band saw blades in large-scale industrial production. Curious to delve deeper into this widely preferred cutting tool? Our Industrial Band Saw Blade Operation course offers a comprehensive resource for mastering the fundamentals. Discover the intricacies of band saw blades and how they excel in meeting the diverse needs of industrial cutting applications.