Injection molding is a widely used process for producing mass quantity of plastic components, but the success of the injection molding process largely depends on one critical factor: mold design. A well-designed mold ensures efficient production, consistent part quality, and minimal downtime. On the other hand, mold design mistakes can result in defects, high costs, and frequent maintenance.

In this blog, we’ll explore some of the most common mold design mistakes and how they can be avoided to improve efficiency and product quality.

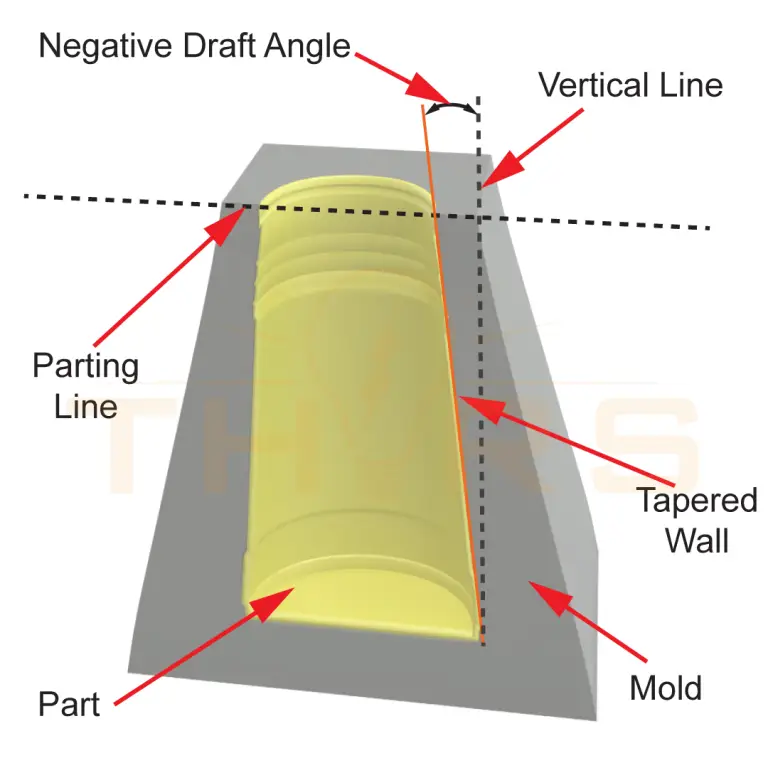

1. Ignoring Draft Angles

A critical mistake is ignoring draft angles, which is the slight taper needed on vertical walls. Without it, the finished part grips the mold too tightly, making it difficult to eject the part and can cause scratches or damage to both the part and the mold itself.

TIP: Always consider draft angles from the very beginning of your part design, not as an afterthought. Use parametric modelling features in your design software to apply a draft during the early stages of design.

2. Inadequate or Inconsistent Wall Thickness

Another common error is designing parts with inadequate or inconsistent wall thickness. Walls that are too thick cool slowly, leading to sink marks, internal voids, and warped parts, while walls that are too thin can be difficult to fill, resulting in incomplete parts.

TIP: The best practice is to maintain a uniform wall thickness throughout the part, using gradual transitions where changes are necessary and consulting material-specific guidelines, which typically recommend a range of 1.5mm to 3.0mm for most plastics. For thick features, “coring out” the material is an effective strategy to achieve a consistent wall and improve cooling.

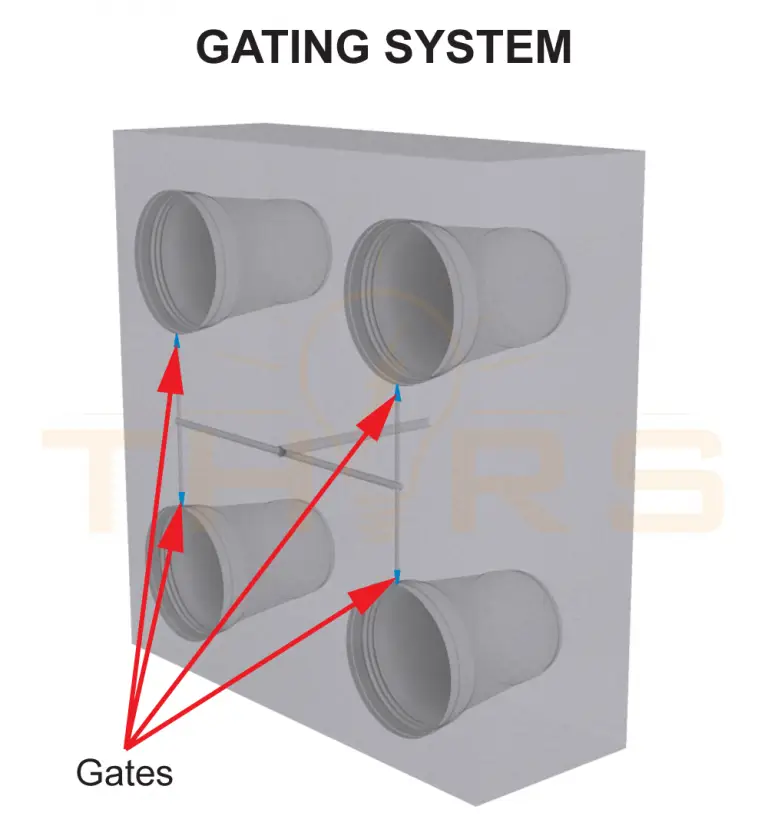

3. Incorrect Gate Placement

Choosing a gate location poorly is a major mistake, as this is where plastic flows into the mold. A bad location can cause warping from unbalanced flow, visible blemishes on cosmetic surfaces, and weak spots in the final part.

TIP: Always use Mold Flow Analysis software to simulate and optimize the plastic flow before manufacturing, and prioritize placing the gate in a discrete, non-critical area that allows for balanced filling and proper venting.

4. Neglecting Venting

Neglecting to add proper vents is a critical error because trapped air has nowhere to go as plastic fills the mold. This can cause compressed air to ignite and create burn marks on the part, prevent the mold from filling completely (short shots), or result in weak weld lines.

TIP: Strategically place shallow vents (typically 0.02-0.05mm deep) at the end of fill paths and in areas prone to trapping air, such as around ejector pins, to allow air to escape without letting plastic leak out.

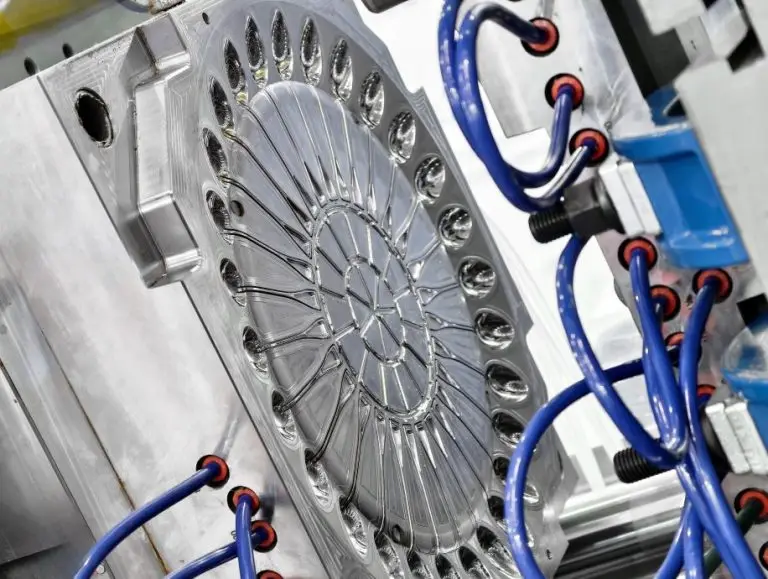

5. Underestimating Cooling Channel Design

Treating cooling line design as an afterthought is a costly mistake. Since cooling takes up most of the production cycle time, inefficient cooling leads to slower production and higher costs. It also causes warping if some sections of the part cool faster than others.

TIP: Design cooling channels to follow the shape of the part as closely as possible for even heat removal. For the best results, consider using conformal cooling channels made through 3D printing, which perfectly match the part’s geometry to drastically speed up production and improve quality.

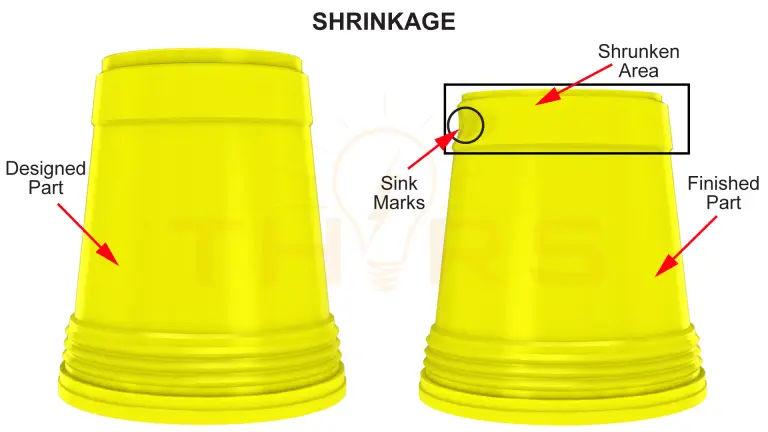

6. Neglecting Material Shrinkage

Neglecting to account for material shrinkage is a fundamental error. Plastic shrinks as it cools, so if the mold isn’t precisely oversized to compensate, the final part will be too small, leading to parts that are out of tolerance and won’t assemble correctly.

TIP: Always use the specific shrinkage data provided by your material supplier for your chosen resin and processing conditions, and always validate your calculations with prototype testing before committing to the final mold.

7. Failure to Consider Maintenance

A common oversight is designing a mold without considering its long-term maintenance. If components like ejector pins, cooling lines, or wear-prone inserts are difficult to access, every repair becomes expensive and causes significant production downtime.

TIP: Design for serviceability by using standard components, incorporating modular inserts for easy replacement, and ensuring critical parts are accessible through removable plates or access ports.

8. Lack of Collaboration in Early Design Stages

Failing to collaborate early in the design process is definitely a mistake. When mold designers work in isolation from product designers and manufacturing engineers, it often leads to designs that are difficult or expensive to produce, requiring costly late-stage changes.

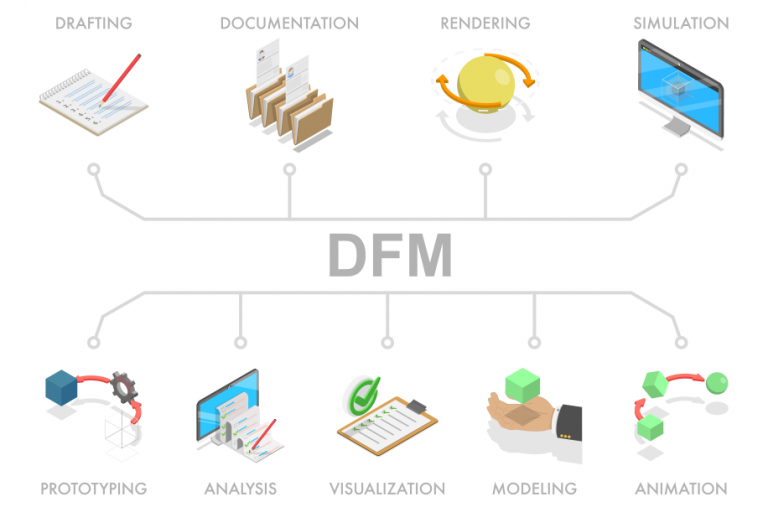

TIP: Engage all stakeholders from the beginning, hold cross-functional design reviews, and adhere to Design for Manufacturability (DFM) principles to ensure the part design is optimized for production from the start.

Mold design is not only about creating a specific output, it’s about ensuring the part can be produced consistently, efficiently, and at the desired quality. By recognizing and avoiding these 8 common mistakes, designers can save time, reduce costs, and deliver better-performing molds.

Learn more! Check out the THORS’ course, Injection Molding Design Fundamentals, along with our other injection molding courses, today.