Aluminum rolling is one of those processes that looks simple on a flowchart—roll a slab, reduce thickness, anneal, trim, coil, finish. But on the shop floor, rolling is a live, tightly coupled system where metallurgy, mechanics, heat, lubrication, and automation all fight and cooperate in real time. The difference between a stable rolling line and a mill stuck usually comes down to one thing: the engineer’s skill.

So, what skills does an aluminum rolling engineer need? Relying on textbook knowledge is no longer enough. Today, more than ever, engineers need practical, plant-ready skills that help deliver gauge, flatness, surface finish, and yield at speed.

Here are the core skills that matter most.

1. Mastery of Rolling Process Fundamentals

A rolling engineer must understand the full rolling route from casting to finishing.

Key process fundamentals include:

- The understanding of the influence of the reduction schedule on deformation behavior and microstructure

- The difference between hot rolling, which concentrates on bulk reduction and high ductility and cold rolling, which focuses on precision reduction and surface finish

- How friction and roll bite affect stability, especially in cold rolling where lubrication is essential

2. Precision Thickness Control

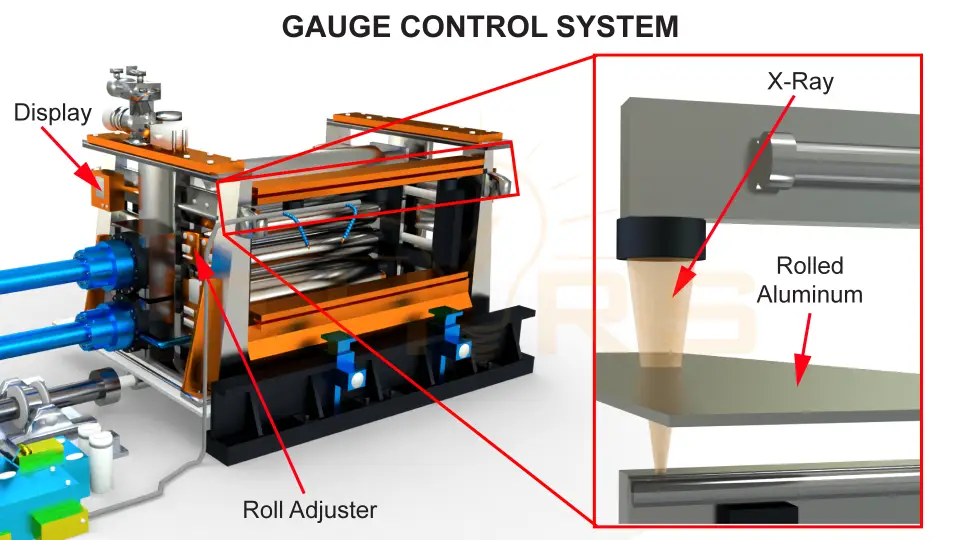

Thickness or gauge control, especially in sheet and foil, is one of the biggest value drivers in aluminum rolling. Engineers today need to understand both the physics of gauge variation and the control systems that correct it.

A rolling engineer should be comfortable with:

- The physics of roll deflection, thermal effects, and the influence of rolling speed on thickness

- Automatic Gauge Control (AGC) that uses sensors measuring exit thickness, feedback loops adjusting roll gap or force in milliseconds

- Supporting systems like X-ray gauges, roll bending, tension control, and PLC coordination to help identify and correct thickness variations during the operation stage itself

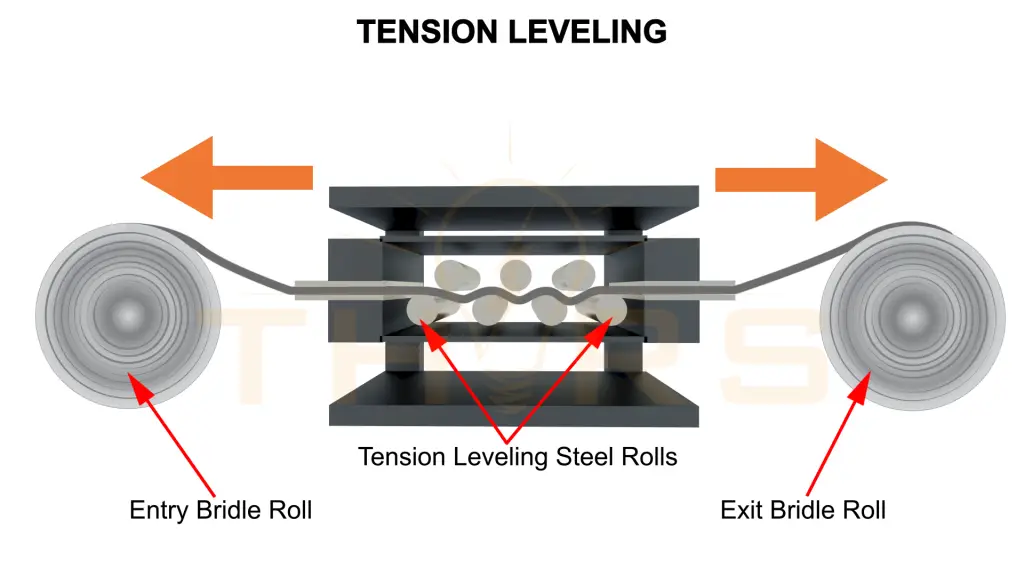

3. Flatness and Shape Control Expertise

Customers don’t just buy “thickness.” They buy flatness, uniformity, and formability. Flatness defects such as wavy edges, center buckle, and quarter buckle are among the most common, and they don’t fix themselves downstream.

Essential flatness skills include:

- Understanding fiber elongation differences across width

- Reading shape maps and interpreting wave or buckle patterns

- Using roll bending, profile control, and tension adjustments to correct shape

4. Defect Recognition and Root-Cause Analysis

Rolling lines lose money in only a few ways: scrap, rework, customer rejection, and downtime. Most of these trace to defects. Today, must-have skills include diagnosing defects quickly and correcting root causes in real-time.

Rolling engineers must recognize:

- Edge cracking from uneven deformation and tensile stress at edges

- Alligatoring, or strip splitting, that occurs when the metal flows unevenly through its thickness during rolling, causing the strip to tear internally and split open

- Surface defects such as scratches, roll marks, pits, oxides from slab preparation, roll condition, or handling

But recognition isn’t enough. Asking questions to find the root causes of the defects is essential, such as:

- Where did it originate? Casting? Hot mill? Cold mill? Finishing?

- Is it mechanical, metallurgical, or control-related?

- What parameter drift caused it—and how do we prevent recurrence?

5. Metallurgical Competence in Aluminum Alloys

Alloy family, temper, and microstructure of aluminum alloys have huge effects on how metal behaves under reduction and heat treatment.

Today’s rolling engineer should understand:

- How different alloy types from 1xxx through 8xxx effect flow stress and work hardening

- The properties of some alloys that are more sensitive to friction and surface damage

- The understanding of the effects of annealing temperature or time in restoring ductility and its final properties

The best aluminum rolling engineers today are systems thinkers. They don’t just “run a mill.” They understand the entire rolling cycle of alloy, rolling mechanics, control systems, defects, and final properties.

That integrated skill set is what lets rolling engineers reduce scrap, hit gauge and flatness consistently, fix defects at the source, and improve yield while keeping production fast and stable. Plants need engineers who can deliver quality over quantity, efficiency with accuracy, and productivity without constantly rushing in and “firefighting.”

To learn more about aluminum rolling, enroll in the THORS Aluminum Rolling Basics Course today.