In power transmission systems, sprockets and chains should run smoothly, quietly, and reliably. But when they do not, sprocket wear becomes a silent destroyer—reducing performance, increasing maintenance costs, and leading to unexpected downtime.

While sprockets are designed to withstand demanding loads, heat, and continuous motion, their longevity depends on correct design, installation, and maintenance. Understanding why sprockets wear out is the first step toward extending their service life.

Let’s explore the top five causes of sprocket wear—and the practical engineering strategies to prevent them.

1. Poor Lubrication

Lubrication plays a critical role in reducing metal-to-metal contact between the chain rollers and sprocket teeth. When lubrication is inadequate or inconsistent, friction increases sharply to result in accelerated tooth wear, surface pitting, and even chain elongation. Symptoms like squeaking, excessive noise, and uneven chain movement are clear indicators that lubrication isn’t doing its job.

Causes

- Using the wrong type of lubricant, either too thin or too viscous

- Lubricant contamination by dust, coolant, or moisture

- Failure to follow a regular re-lubrication schedule

- Over-lubrication, which can attract dirt and abrasive particles

Prevention Tips

- Use a lubricant specifically formulated for chain drives, typically one that penetrates between chain links and maintains a thin oil film under load.

- Apply lubrication to the inside of the chain where it contacts the sprocket teeth.

- Consider automatic lubrication systems for continuous, controlled application.

- Keep the drive area clean to prevent dust or grit from turning lubricant into an abrasive paste.

2. Misalignment between Sprockets

Misalignment occurs when the driving and driven sprockets are not perfectly aligned on the same plane. Even small angular or parallel misalignments can cause the chain to drive unevenly, concentrating wear on one side of the sprocket teeth. This asymmetrical contact leads to hooked or sharp-edged teeth, excessive vibration, and premature chain fatigue.

Causes

- Improper installation or mounting errors

- Shaft bending or deflection during operation

- Uneven foundation or poor structural rigidity

- Worn bearings or loose mounting bolts

Prevention Tips

- During installation, use laser alignment tools or straightedges to ensure the sprocket faces are parallel and aligned within tight tolerances.

- Check alignment periodically, especially after maintenance or heavy load events.

- Replace worn bearings or bent shafts immediately.

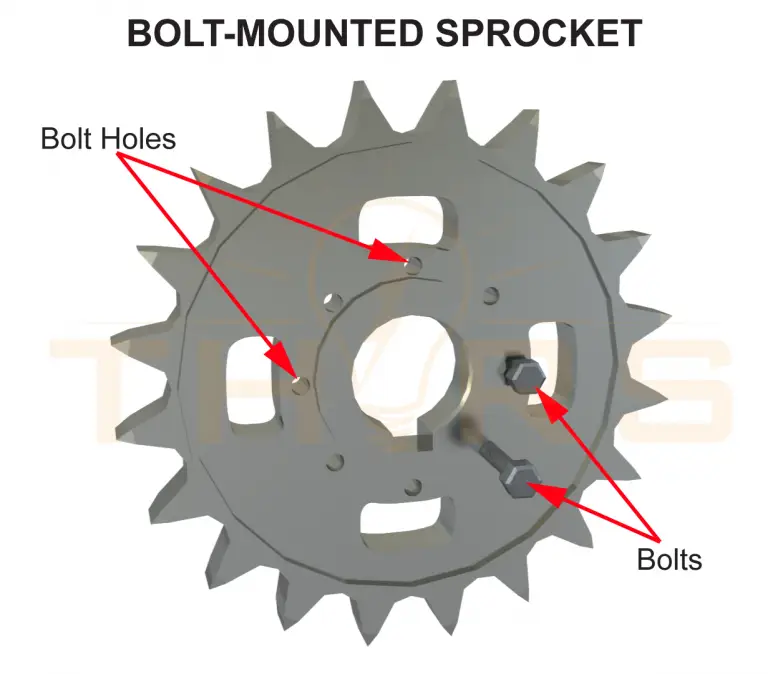

- Use flanged or self-aligning sprockets in systems with slight unavoidable misalignment.

3. Improper Chain Tension

Improper chain tension, whether too tight or too loose, can drastically reduce sprocket and chain life. Over-tensioning increases bearing loads, friction, and tooth pressure. Under-tensioning leads to chain whipping, skipping, and uneven load transfer. Both conditions accelerate wear on sprocket teeth and chain rollers, often visible as “cupping” or pitting on the contact surfaces.

Causes

- Manual tensioning without reference to manufacturer specifications

- Chain elongation or stretching due to wear

- Thermal expansion or load variation in long drives

- Neglecting to re-tension after initial run-in

Prevention Tips

- Maintain chain sag between 2% and 4% of the center distance.

- Check tension after the first 100 hours of operation and adjust as necessary.

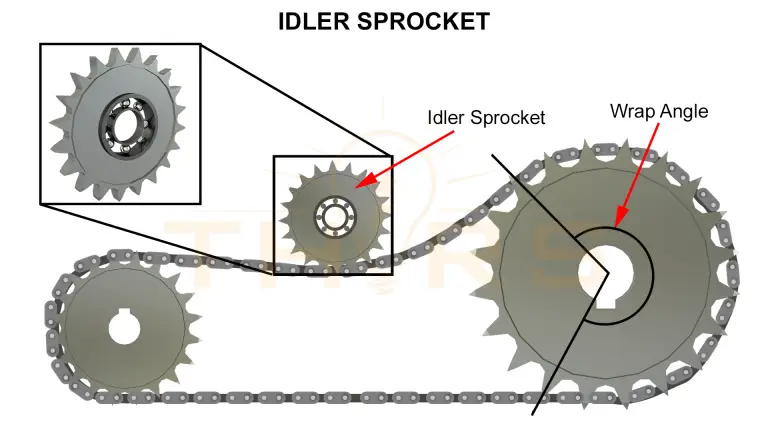

- For critical applications, use automatic chain tensioners or idler sprockets to maintain constant tension through setting the right wrap angle.

- Replace elongated chains promptly. Running a worn chain on a new sprocket accelerates tooth wear.

4. Contaminated and Harsh Operating Environments

Dirt, dust, metal shavings, and moisture are some of the biggest enemies of sprockets. Contaminants act like abrasives between the chain and teeth, grinding away material with every revolution. In damp or chemical-rich environments, corrosion adds another layer of damage—undermining the hardness and surface finish of the sprocket.

Causes

- Lack of protective covers or guards

- Operating in dusty, sandy, or corrosive environments for mining, agriculture, or food processing applications

- Using uncoated or untreated sprockets in humid or outdoor setups

- Poor maintenance —allowing the build-up of debris

Prevention Tips

- Install chain guards or enclosures to minimize contamination.

- In corrosive conditions, choose stainless steel or surface-treated sprockets such as black oxide or nickel-plated sprockets.

- For extreme environments, use self-lubricating polymer sprockets that resist rust and grit.

- Regularly clean the drive system using non-corrosive solvents and soft brushes.

5. Incorrect Material with Less Surface Hardness

The wrong material choice or inadequate surface hardness can lead to premature sprocket wear—especially in high-load, high-speed, or abrasive applications. A sprocket that’s too soft will wear out quickly, while one that’s too hard may become brittle and prone to cracking under shock loads; hence, balance is the key.

Causes

- Using mild steel sprockets where alloy or hardened steel is required

- Lack of surface treatments like induction hardening or carburizing

- Overlooking the need for corrosion-resistant coatings

- Reusing worn sprockets without checking their hardness integrity

Prevention Tips

- Select sprockets made from hardened alloy steel having a hardness between 45–60 HRC for heavy-duty drives.

- For corrosive environments, consider stainless steel or nickel-plated options.

- Apply surface treatments like nitriding or shot peening to improve fatigue resistance.

- Match sprocket hardness to chain roller hardness for balanced wear.

Sprocket wear doesn’t have to be inevitable, it can be prevented. By addressing these five key factors—lubrication, alignment, tension, contamination, and material selection, one can dramatically extend sprocket life, reduce downtime, and maintain consistent performance.

In modern maintenance practice, attention to these engineering details transforms a simple mechanical component into a reliable, long-lasting asset. To learn more about sprockets, their types and manufacturing processes, the THORS Sprocket Basics Course would be a good place to start!