What is supply chain optimization?

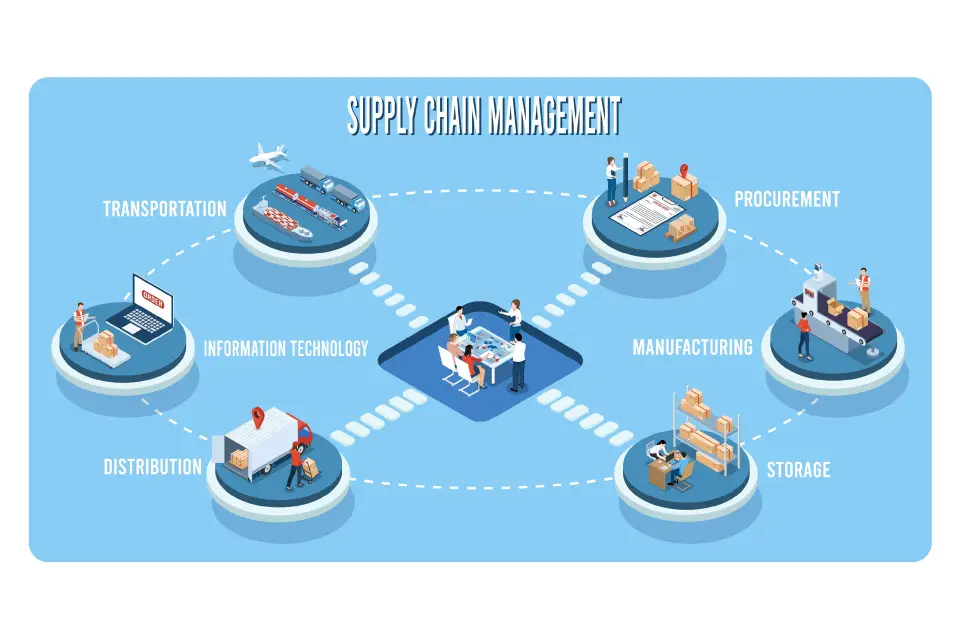

Supply chain optimization is the process of enhancing the efficiency and effectiveness of a supply chain by strategically planning, executing, and continuously improving its various stages. Highlighting the importance of supply chain optimization, the goal is to achieve optimal outcomes in areas such as cost reduction, operational efficiency, customer satisfaction, speed, reliability, risk mitigation, and adaptability. This involves refining processes across procurement, production, distribution, and logistics to ensure the supply chain functions seamlessly while meeting organizational and customer needs.

What is the importance of supply chain optimization?

Supply chain optimization directly impacts a company’s ability to operate efficiently, satisfy customers, and remain competitive in the hence it is considered a crucial factor in business planning. Some of the reasons why supply chain optimization is important are:

- Reducing the operational costs by streamlining processes, minimizing waste, and improving resource utilization.

- Ensuring that every component, from production to delivery, operates as efficiently as possible.

- Maintaining timely delivery of high-quality products and gaining customer satisfaction.

- Responding quickly to changes in demand, supply disruptions, and market conditions.

- Identifying potential risks and developing contingency plans that minimize the impact of disruptions.

- Reducing the environmental impact by minimizing waste, improving energy efficiency, and promoting the use of sustainable materials and practices.

What are the strategies involved in supply chain optimization?

Supply chain optimization involves a variety of strategies aimed at improving efficiency, reducing costs, and enhancing overall performance. Some of the strategies include:

- Demand Forecasting and Planning : Planning and forecasting requirements with the help of advanced analytics to predict future demand helps to maintain inventory levels when the market needs them. Collaborative working with partners and stakeholders creates a shared understanding of demand forecasts and production plans.

- Inventory Management: Managing the inventory involves having just the right amount of inventory and minimizing inventory holding costs by receiving goods only as they are needed in the production process. It also makes sure that a buffer stock is maintained to protect against unforeseen disruptions in supply or spikes in demand. Inventory management prioritizes the critical items based on their category.

- Lean and Six Sigma: Implementing lean methodologies to eliminate waste, improve process efficiency, and enhance value for customers. Implementation of six sigma techniques to identify and remove causes of defects and variability in manufacturing and business processes.

- Supplier Relationship Management: Supplier relationship management involves diversification in sourcing materials from multiple suppliers to mitigate the risk of disruption from any single supplier and building strong relationships with key suppliers through joint development initiatives and information sharing. It also regularly assesses the supplier performance to ensure quality and reliability.

- Technology Integration: Implementing IoT devices to monitor and manage inventory levels, track shipments, and optimize helps companies leverage technology to increase their efficiency. Utilizing and for predictive analytics, demand forecasting, and decision-making support. Enhancing transparency and security in supply chain transactions through blockchain technology ensures integrity and trust across the entire process.

- Process Automation: Automation of processes through robots for repetitive tasks such as order processing, invoicing, and data entry reduces human error and improves efficiency. Using Automated Guided Vehicles (AGVs) for material handling in warehouses and manufacturing facilities help to streamline.

Conclusion

Optimizing the supply chain for manufacturing resilience involves a multifaceted approach. Diversifying suppliers, embracing technology, building strong supplier relationships, and optimizing inventory management will help manufacturers navigate uncertainties driving better business outcomes and competitive advantage.