Metal casting is the manufacturing process of pouring molten metal into a mold to create a required shape. While metal casting has been an important industrial process for centuries, the manufacturing sector is increasingly focused on sustainability in metal casting and reducing the environmental impact of its operations. There are several ways that metal casting can be made more sustainable while increasing the benefits of sustainability.

One key method to create sustainability in metal casting is by reducing the amount of energy required to melt the metal. This can be achieved through the use of energy-efficient furnaces and the recycling of scrap metal. According to a report by the United Nations Industrial Development Organization (UNIDO), using recycled metal in the casting process can reduce energy consumption by up to 74% compared to using virgin metal.

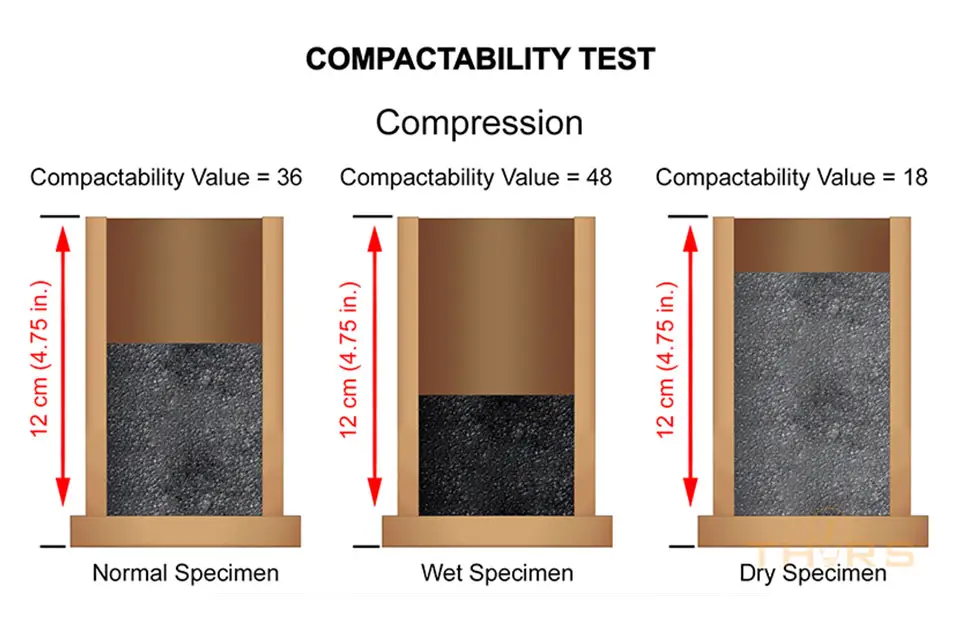

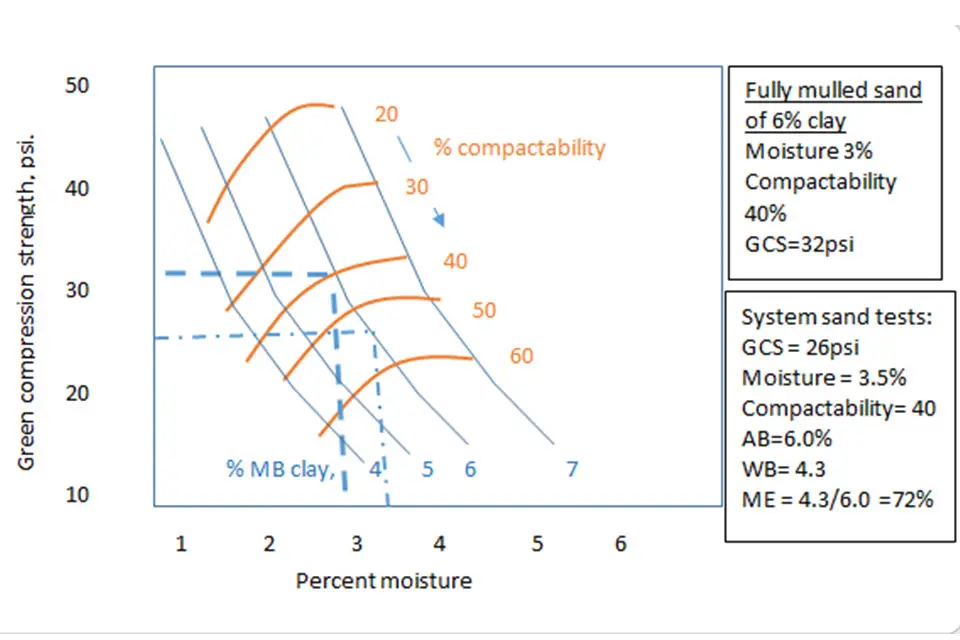

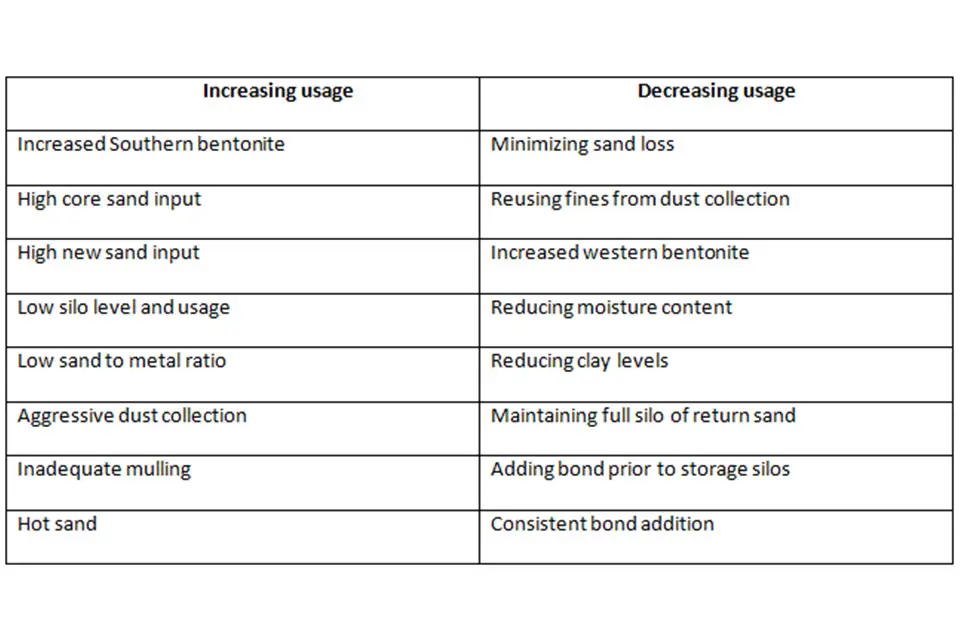

Another way to improve the sustainability in metal casting is by reducing waste and emissions. The use of sand molds, which is one of many recyclable byproducts of metal casting processes, can help reduce waste. Additionally, the use of low emission binders can help reduce the number of harmful pollutants released during the casting process.

The metal casting industry is also exploring new materials and processes that are more sustainable. For example, some manufacturers are using bio-based binders instead of traditional petroleum-based binders. Others are experimenting with 3D printing technology to reduce material waste and improve the precision of the casting process.

The benefits of sustainable metal casting go beyond reducing manufacturing operations’ environmental impact. Sustainability in metal casting can also lead to cost savings through reduced energy consumption, improved efficiency, and reduced waste. Additionally, consumers often view companies that prioritize sustainability more favorably, which can lead to increased brand loyalty and customer satisfaction.

In conclusion, sustainability is an increasingly important consideration in the metal casting industry. By reducing energy consumption, waste, and emissions, and exploring new materials and processes, manufacturers can make their operations more sustainable and reap the benefits of improved efficiency and cost savings. With the growing focus on sustainability across manufacturing industries, it’s clear that sustainable metal casting will continue to be an important area of innovation and growth in the years to come.

For more on metal casting, check out one of our many casting courses!