Course Description

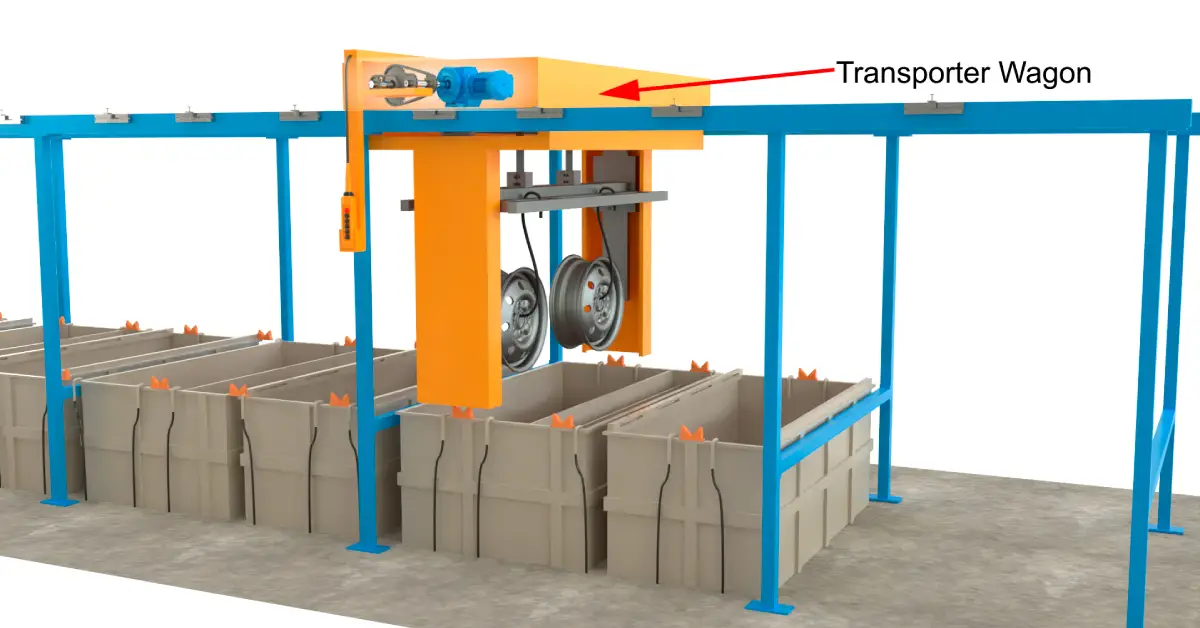

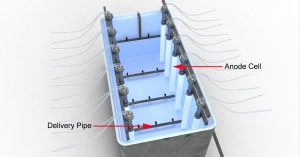

The THORS Cathodic Electrodeposition (CED) Painting Basics course is relevant for learners who are new to the industry, as well as experienced learners who require a deeper knowledge of the systems and equipment involved in the painting processes. The CED painting systems function in a coordinated way ensuring optimal productivity. This introductory course offers an interactive learning experience that allows learners to gain an in-depth understanding of the CED process including the pretreatment, painting, and support processes.

Who will benefit from this cathodic electrodeposition (CED) painting course?

Quality, manufacturing, engineering, designing, purchasing, and sales functions at organizations that require an understanding of sprockets.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Cathodic Electrodeposition (CED) Painting Basics

*upon successful completion

Related Posts

Upskilling in the Manufacturing Industry with THORS

In today’s rapidly evolving manufacturing industry, staying up to date with the latest technologies and processes is crucial to remaining competitive. Upskilling in the manufacturing industry

The Role of Virtual Reality in Technical Training

In the rapidly evolving landscape of technology and industry, virtual reality (VR) in technical training is leading a revolutionary transformation in how professionals are trained.

Injection Mold Design: How the Right Strategies Can Optimize Cycle Time and Production

In injection molding, every second of cycle time directly impacts profitability. Strategic mold design decisions can reduce cycle times by 20-40%, translating to significant production