Course Description

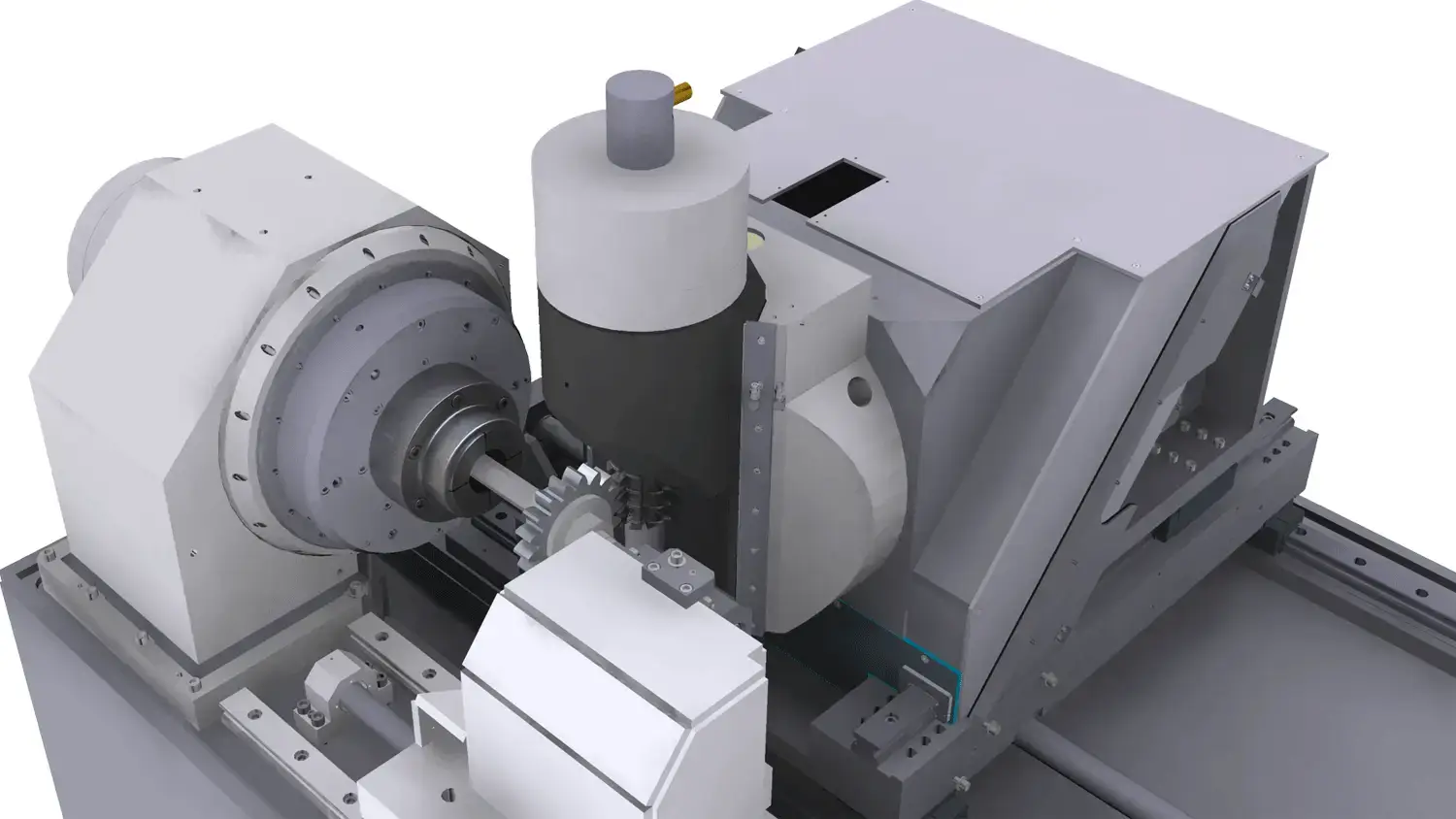

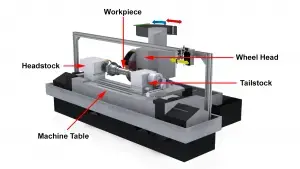

The Gear Hobbing Video Series 1 course introduces learners to the basic functions, components, and terminology associated with modern gear hobbing machines. The series also addresses the axis coordinate system applied to hobbing, the required hobbing tools such as hobs and arbors, and the workholding devices commonly used for the process.

Who will benefit from this Gear Hobbing video series?

Operators, Inspectors, Sales, and Purchasing.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Gear Hobbing Video Series 1

*upon successful completion

Related Posts

The Role of eLearning in Compliance Training

In today’s fast-changing business environment, effective compliance training is more crucial than ever. eLearning in compliance training has emerged as a powerful tool for ensuring

The Essential Skills of Modern Purchasing Professionals

In my professional career that spans more than three decades, I have had the privilege of working closely with purchasing. I can attest to the

Orientation versus Onboarding: Understanding the Differences

When discussing “orientation versus onboarding”, it’s vital to recognize that, though frequently conflated, they serve distinct purposes in the professional environment. Despite both focusing on