Course Description

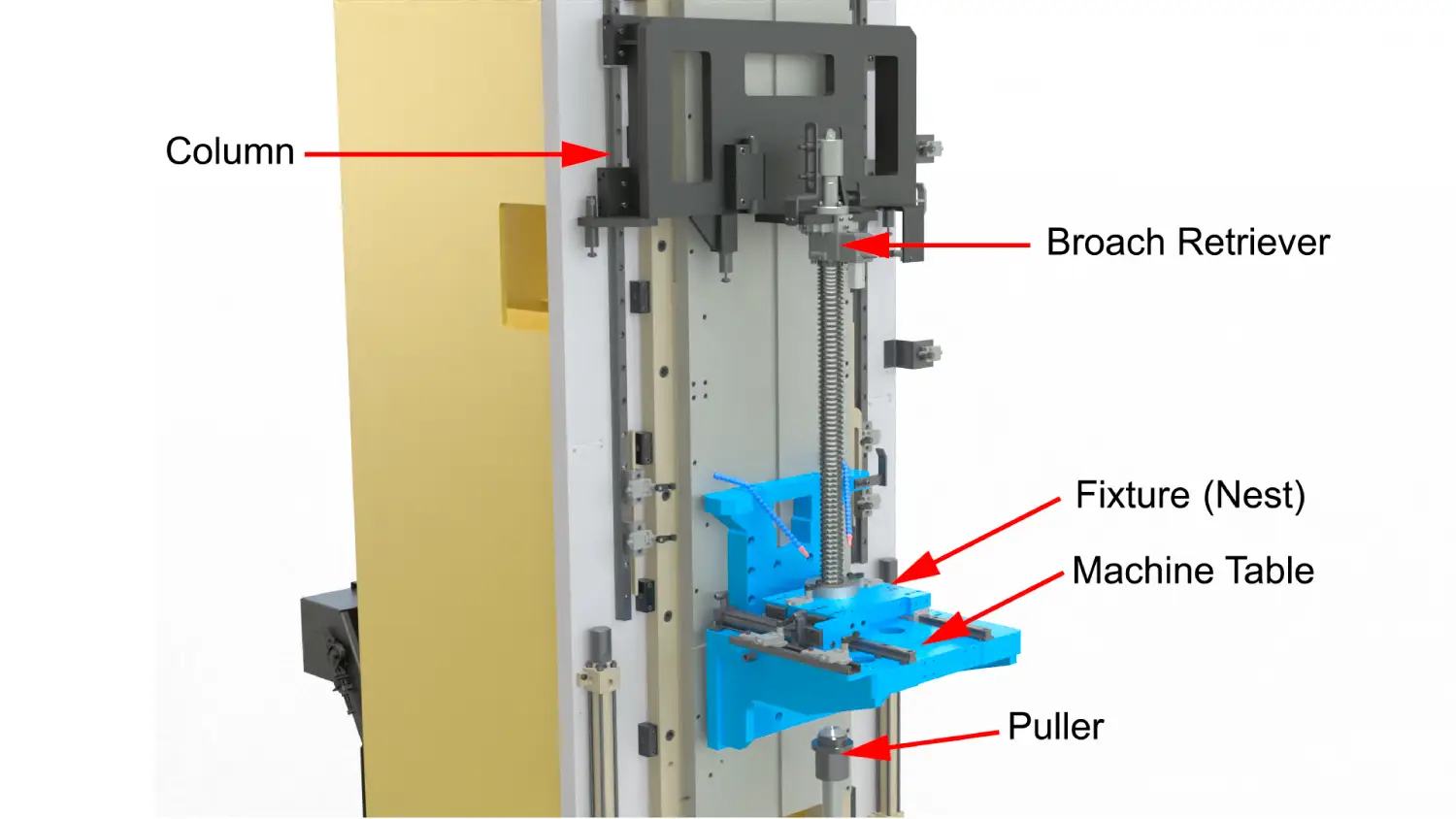

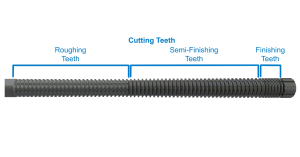

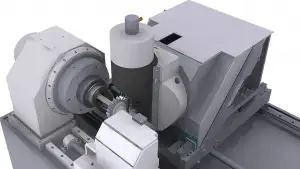

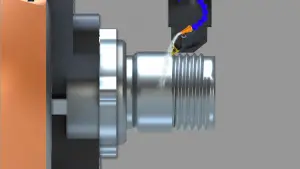

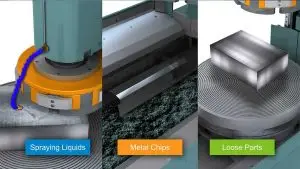

The THORS Broaching Video Series course is designed to introduce and familiarize learners with the basic functions, components, and terminology associated with broaching machines. The series also addresses important concepts to the broaching process, such as cutting parameters and cutting tools, as well as best practices and troubleshooting.

Who will benefit from this Broaching Types, Process, and Parameters video series?

Manufacturing Engineers, Design Engineers, Estimating Teams, Quality, Purchasing, Small Business Owners and others at organizations that operate broaching machines will benefit from the broaching video series.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Broaching Video Series

*upon successful completion

Related Posts

The Essential Skills of Modern Purchasing Professionals

In my professional career that spans more than three decades, I have had the privilege of working closely with purchasing. I can attest to the

5 Ways to Reduce Human Errors in Manufacturing

We cannot change the human condition, but in manufacturing we can certainly improve the way people work, where they work, and what systems they use.

Cross-Cultural Training Benefits

Understanding Cross-Cultural Training In today’s interconnected world, businesses are expanding beyond borders. To thrive globally, organizations must equip their employees with cross-cultural skills. Cross-cultural training