Course Description

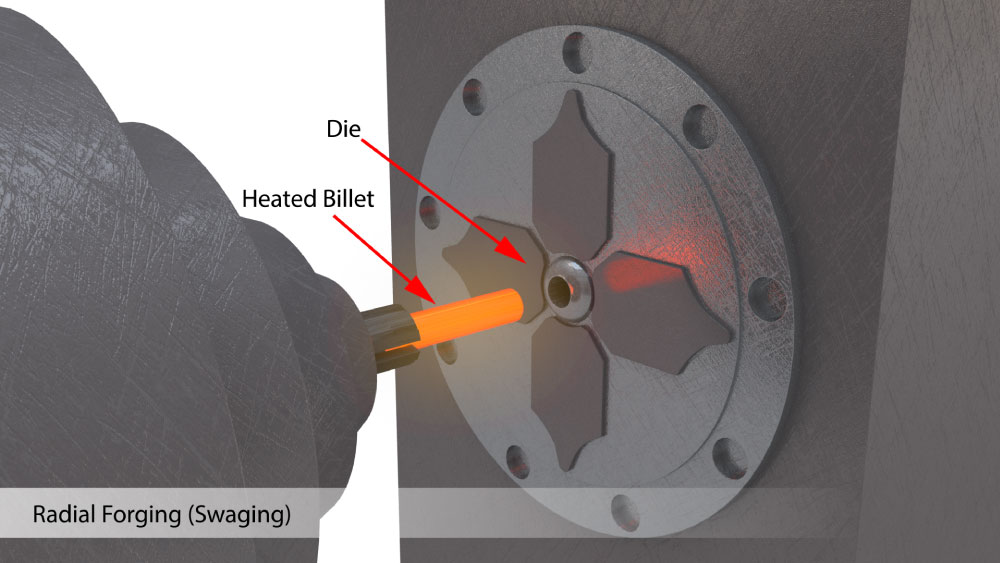

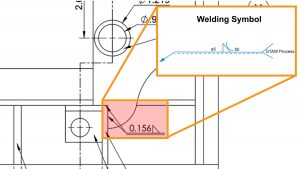

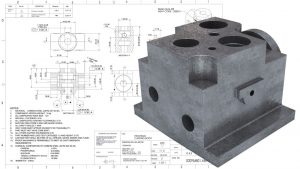

The THORS Engineering Drawings for Forgings course offers instruction on mechanical drawing interpretation relevant for the forging industry, with a focus on forging inspection print analysis. The course begins with a review of forge shop process planning and other fundamental concepts related to forging operations, then offers a targeted examination of key concepts observed on a variety of typical forged part inspection drawings. Drawing interpretation is explained using animations, then reinforced via interactive full-size reference prints.

Who will benefit from this Engineering Drawings for Forgings course?

Quality, manufacturing, engineering, purchasing, and sales functions at organizations that perform forging operations; Students.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Engineering Drawings for Forgings

*upon successful completion

Related Posts

The Essential Skills of Modern Purchasing Professionals

In my professional career that spans more than three decades, I have had the privilege of working closely with purchasing. I can attest to the

Certificate Programs vs Completion Certificates

Certificate programs and completion certificates are both types of educational programs that can provide valuable training and skills to individuals in a variety of fields.

Women in Manufacturing: An Interview with Kavita Krishnamurthy

As part of a tribute to women in manufacturing, we at THORS eLearning Solutions decided to showcase one of our own, Kavita Krishnamurthy. Kavita is