Course Description

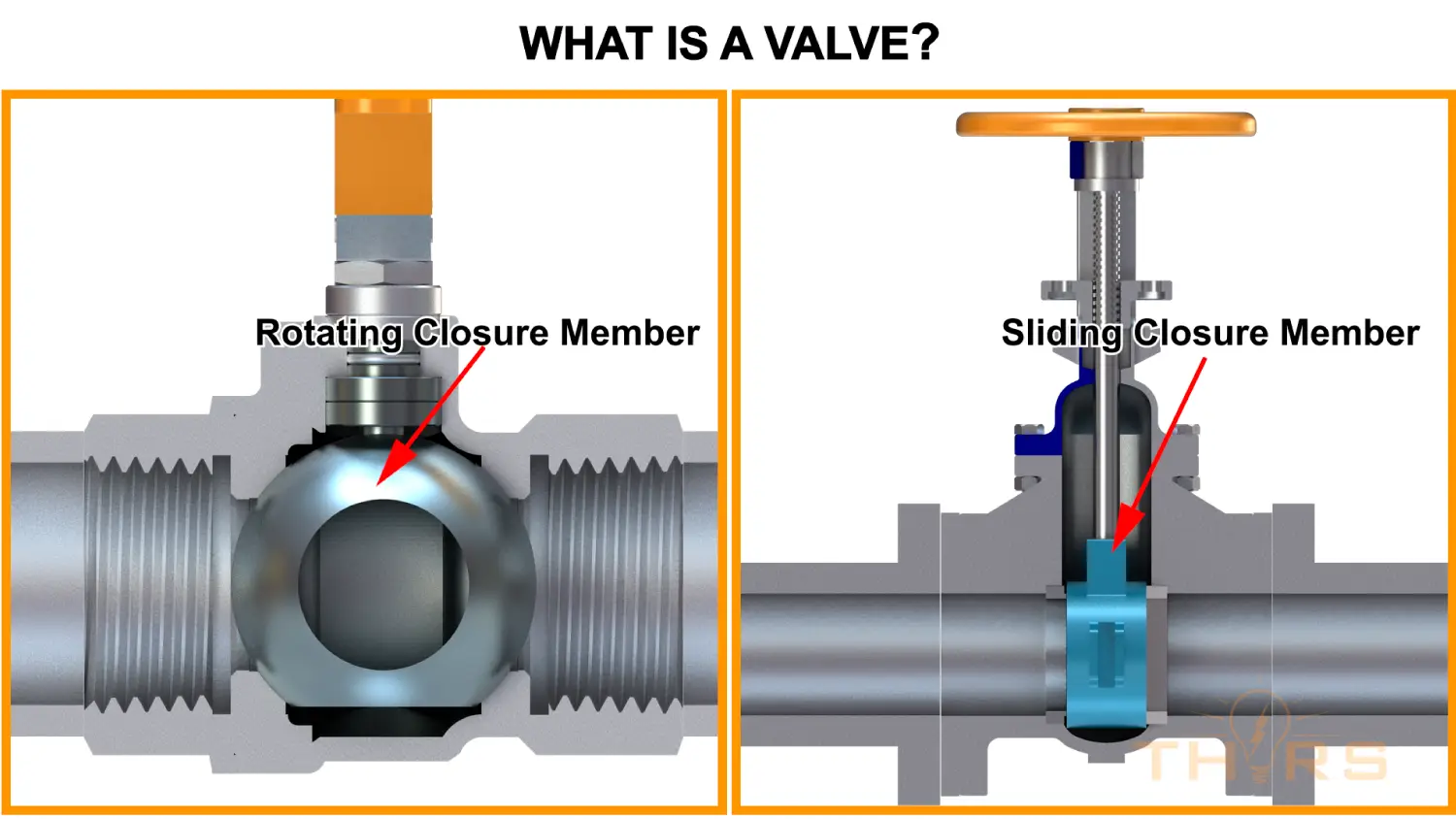

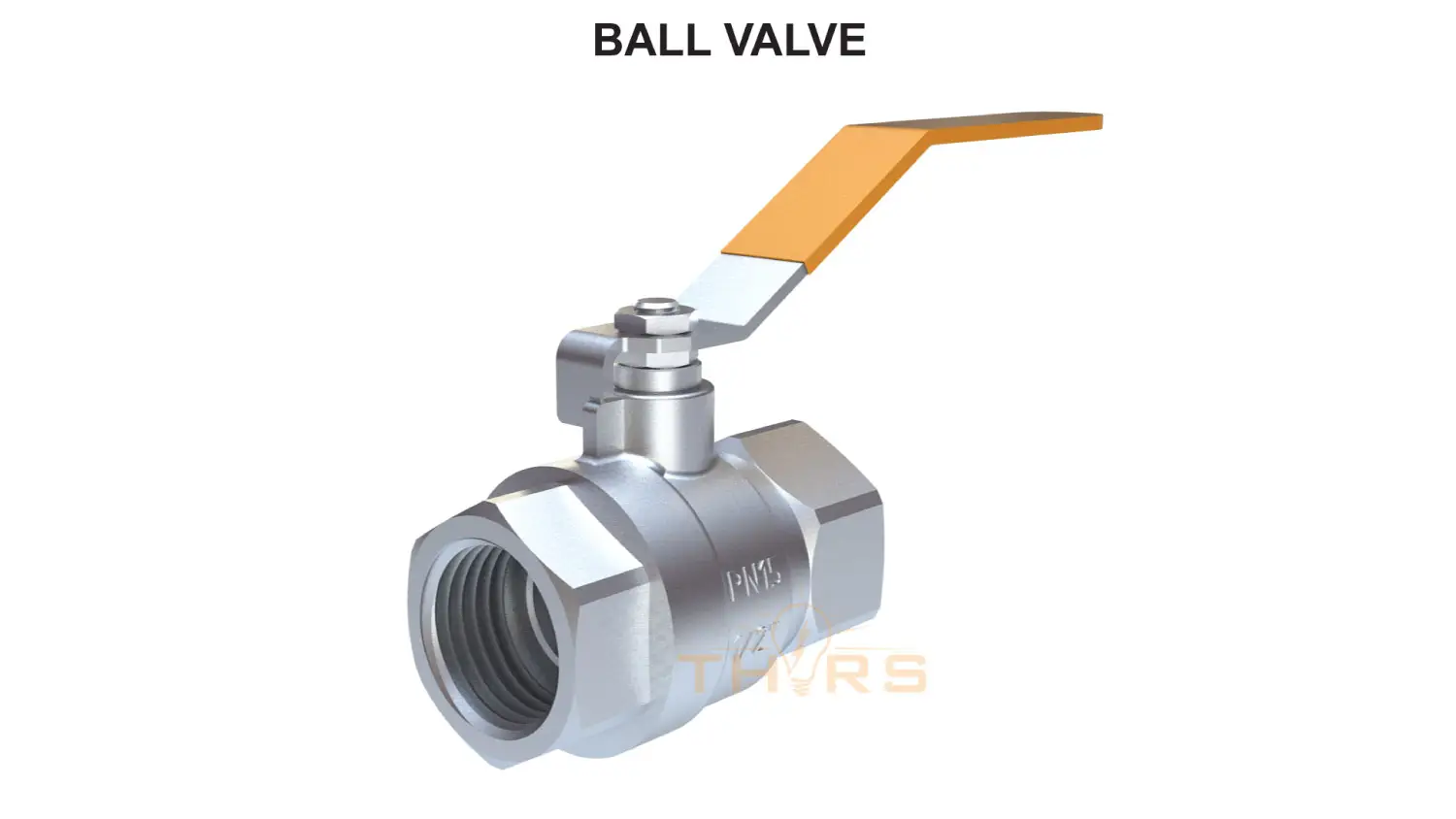

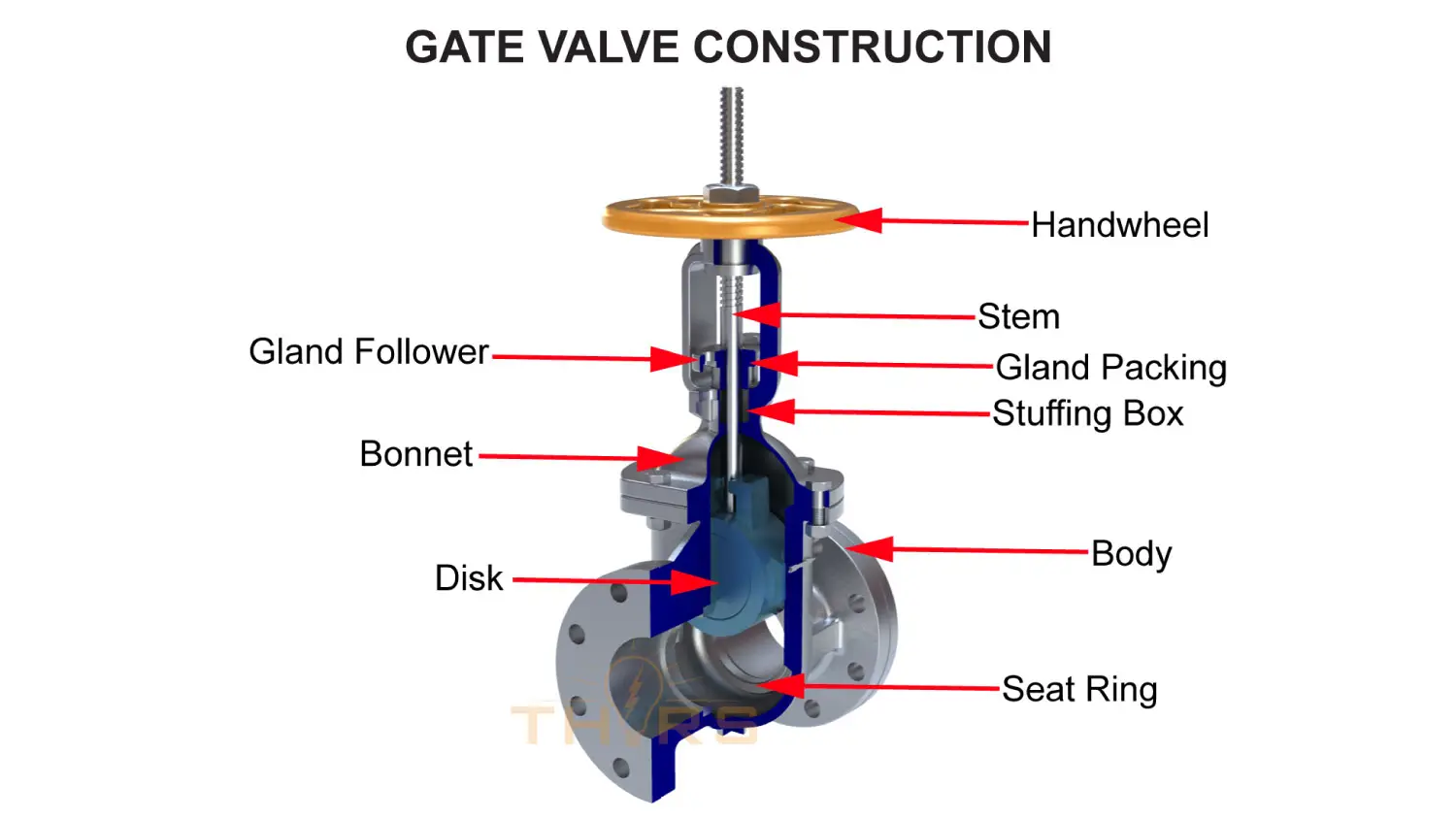

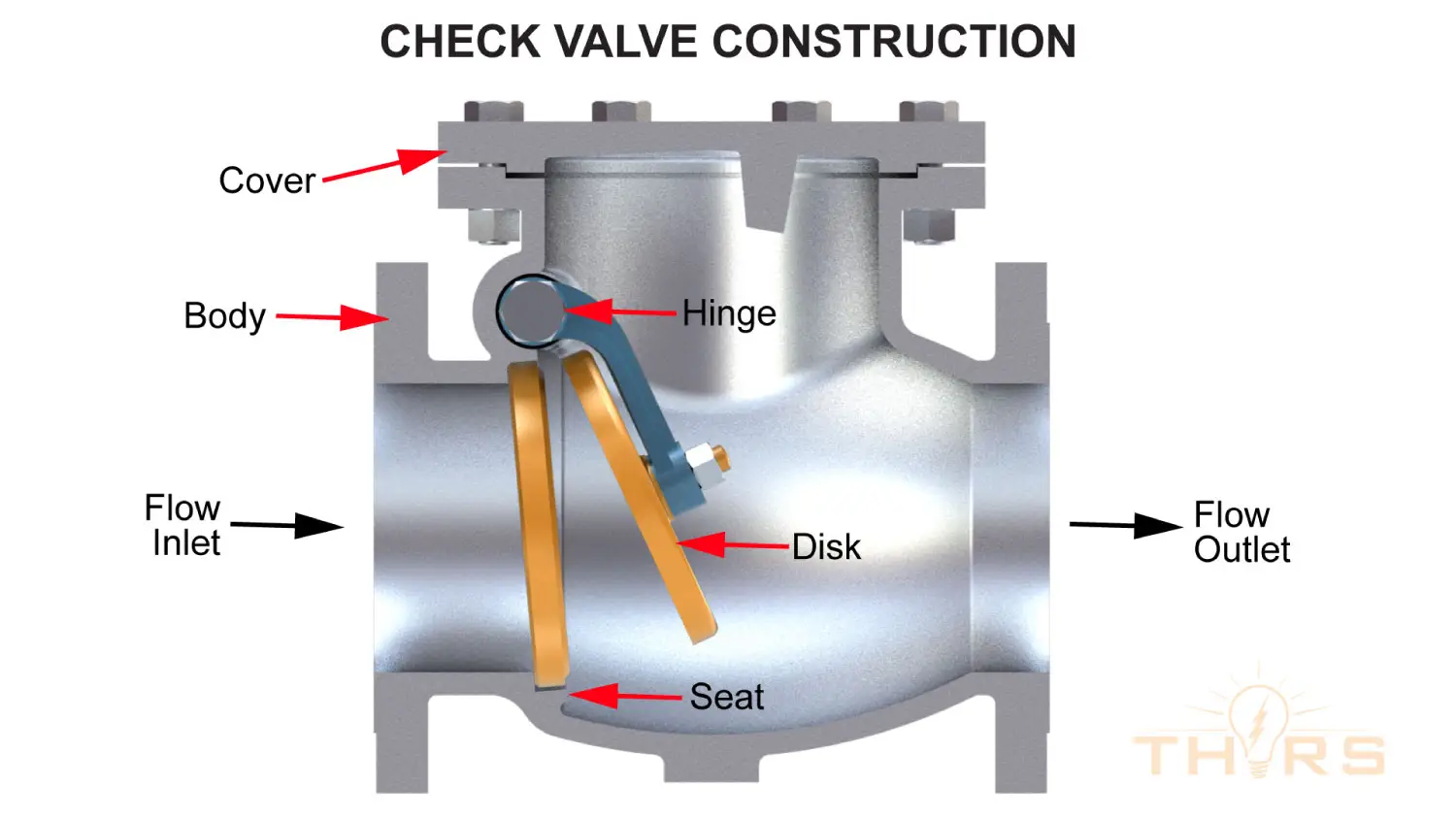

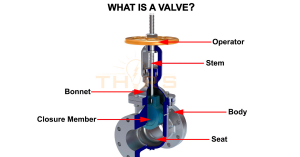

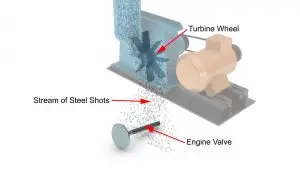

Valves are fundamental to any industry engaged in the transport and regulation of flowing media. The visually engaging and highly interactive THORS Valve Basics course introduces the learners to the diverse world of valves. Under the broad categories of linear motion valves and rotary motion valves, the course offers a comprehensive overview to the construction, classification, working principle, applications, advantages, and limitations of different types of valves.

Who will benefit from this Valves course?

Quality, manufacturing, engineering, designing, purchasing, and sales functions at organizations that require a basic understanding of valves

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Valve Basics

*upon successful completion

Related Posts

Examining Gear Hobbing Equipment and Tools

What is gear hobbing? Gear hobbing is considered a generating process and is the most common method of producing teeth in gears of all sizes.

V belts, an Overview

To explain any belt drive system in a simple way, imagine two separate rollers bound by a thread which runs over their outer periphery, which

Training Perspective: Looking Back to Look Ahead

Companies are constantly reviewing ways to reduce costs and keep positive margins. During times of economic recession, external pressures from competitors as well as internal pressures