Course Description

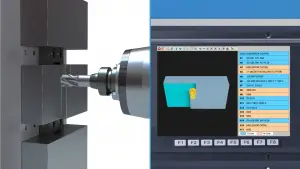

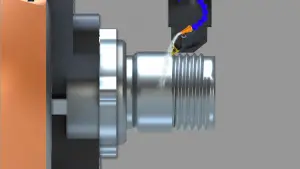

The Vertical Machining Center Video Series 1 course introduces learners to the basic functions, components, and terminology associated with modern vertical machining centers. The series also addresses machining center surface operations, such as milling, and a variety of hole machining operations, such as drilling, tapping, and reaming. Tool holders and tool clamping systems are also addressed.

Who will benefit from this Vertical Machining Process video series?

Operators, Inspectors, Sales, and Purchasing.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Vertical Machining Center Video Series 1

*upon successful completion

Related Posts

5 Reasons Why a Culture of Learning can Lead to Success

Learning is continuous. After all, there are always new skills to learn and techniques to adopt. A culture of learning in an organization can also

Gear Hobbing Cutting Parameters to Optimize the Hobbing Process

What are the Primary Gear Hobbing Cutting Parameters? Primary gear hobbing cutting parameters include the radial feed rate, the axial feed rate, the work spindle

Boosting Employee Engagement in eLearning

Introduction In the realm of modern workplaces, boosting employee engagement in eLearning has become a pivotal factor in fostering productivity, job satisfaction, and overall organizational