Course Description

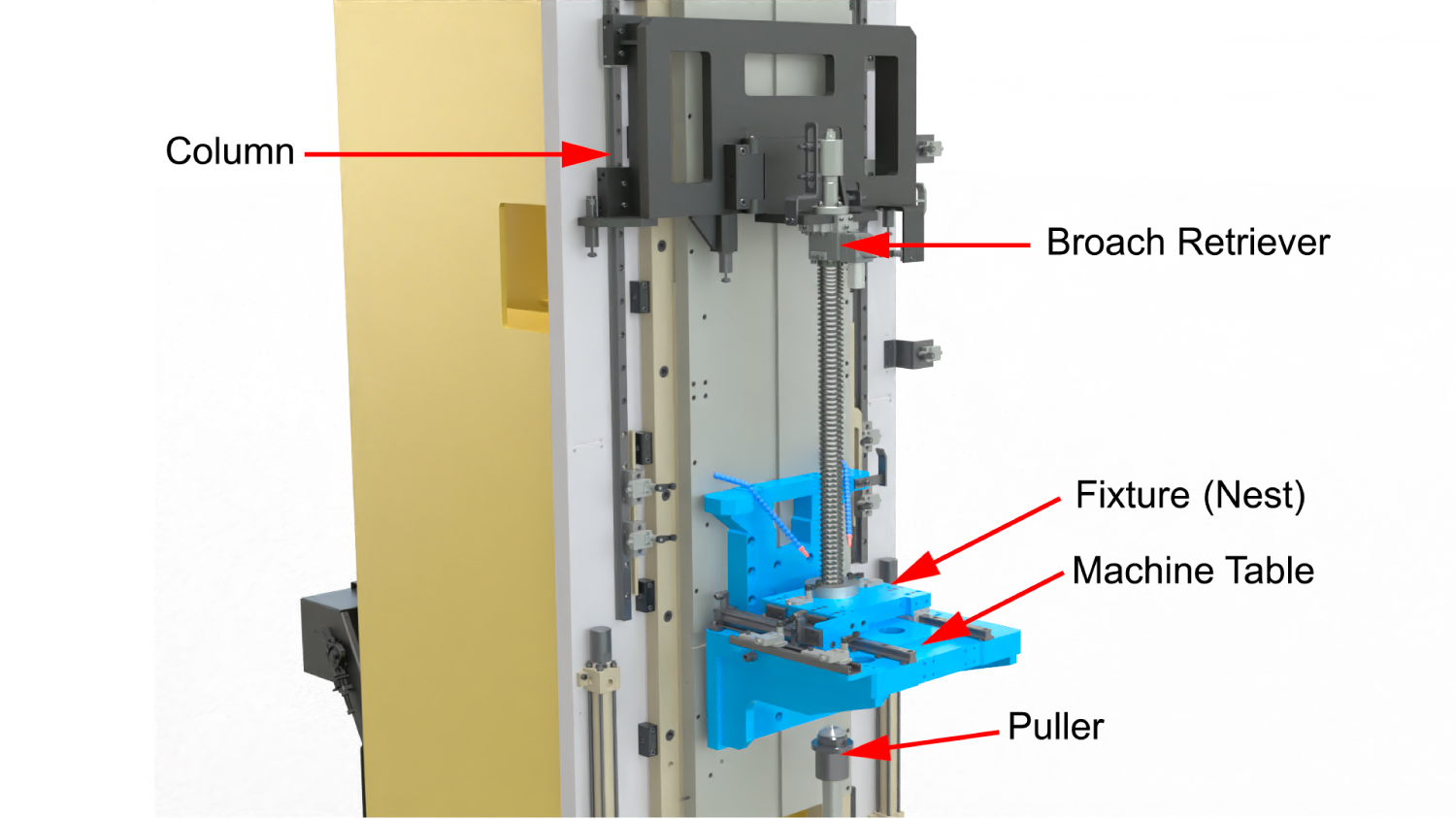

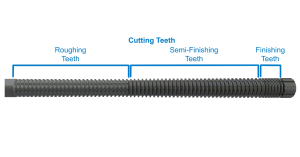

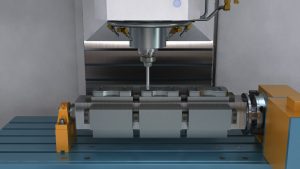

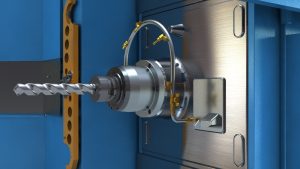

The THORS Broaching Video Series course is designed to introduce and familiarize learners with the basic functions, components, and terminology associated with broaching machines. The series also addresses important concepts to the broaching process, such as cutting parameters and cutting tools, as well as best practices and troubleshooting.

Who will benefit from this Broaching Types, Process, and Parameters video series?

Manufacturing Engineers, Design Engineers, Estimating Teams, Quality, Purchasing, Small Business Owners and others at organizations that operate broaching machines will benefit from the broaching video series.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Broaching Video Series

*upon successful completion

Related Posts

5 Reasons Why a Culture of Learning can Lead to Success

Learning is continuous. After all, there are always new skills to learn and techniques to adopt. A culture of learning in an organization can also

Orientation versus Onboarding: Understanding the Differences

When discussing “orientation versus onboarding”, it’s vital to recognize that, though frequently conflated, they serve distinct purposes in the professional environment. Despite both focusing on

Developing Soft Skills in the Tech Industry

Soft skills in the tech industry, where precision and expertise are paramount, might seem secondary. However, soft skills such as communication, teamwork, and problem-solving, play