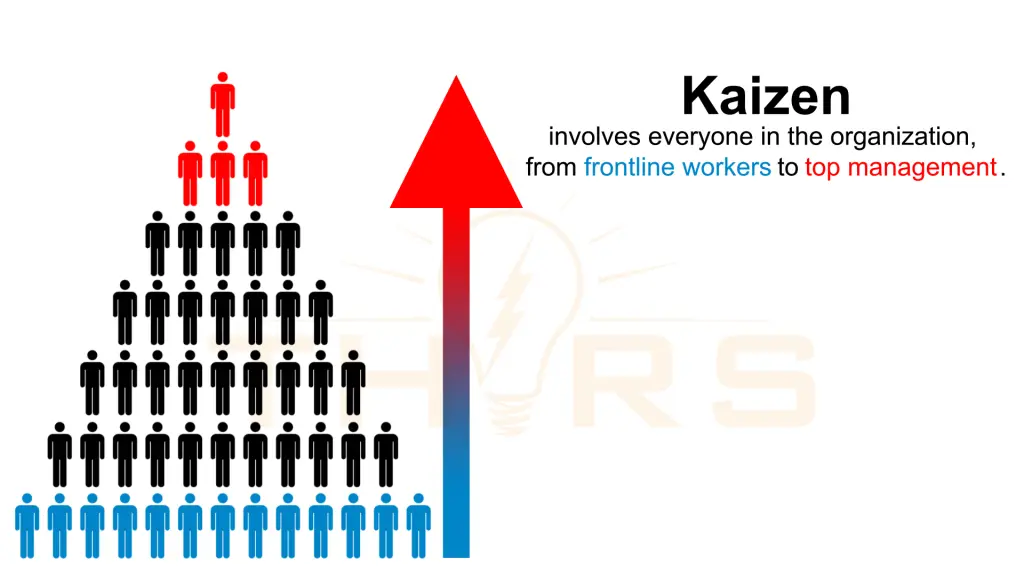

In today’s fast-paced and ever-changing business world, manufacturing excellence is a crucial requirement for all organizations, and a successful way to achieve this is manufacturing excellence with Kaizen. Kaizen is a Japanese term that means “change for the better” or “continuous improvement.” Therefore, the main of Kaizen is making small, incremental improvements to processes and systems on a regular basis. Kaizen involves everyone in the organization, frontline workers to top management. It’s a team effort that requires communication, collaboration, and a willingness to embrace change.

What Is the Kaizen Methodology?

The Kaizen methodology is unique from other process improvement disciplines, such as Lean Management and Six Sigma.

Lean Management seeks to improve process parameters such as speed, quality, and innovation by reducing waste and various bottlenecks.

Six Sigma seeks to reduce or eliminate defects by using data points and a disciplined methodology to process improvement.

Lean Management and Six Sigma are both considered top-to-bottom methodologies, or top-down methodologies, that are first implemented in management spheres.

Kaizen, on the other hand, is considered a bottom-to-top methodology, or bottom-up methodology. Implementing Kaizen is best achieved when the operators and employees on the shop floor adopt the mindset of continuous improvement, and the philosophy continues up the ladder.

What Are the Tools Used in the Kaizen Methodology?

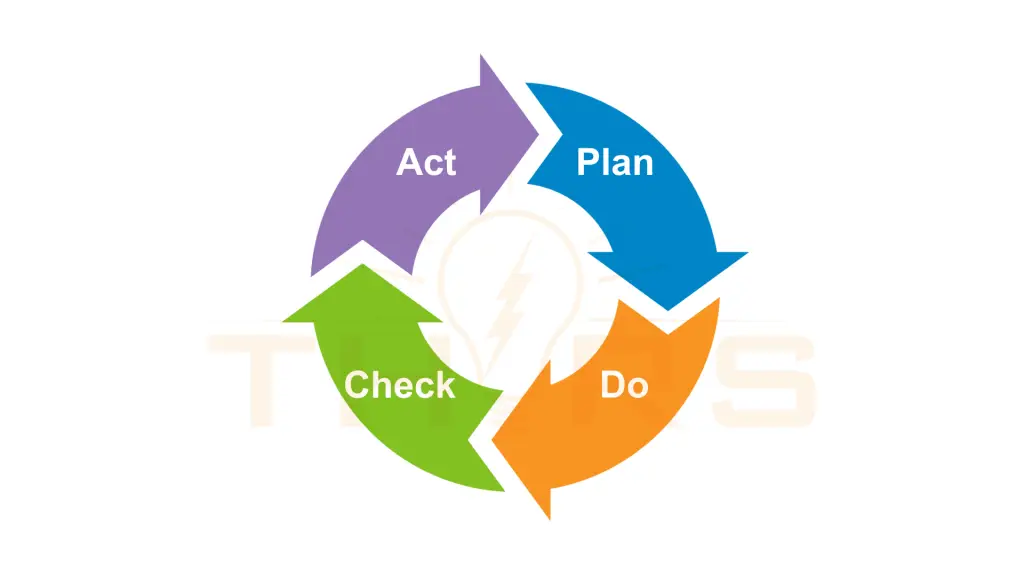

The manufacturing excellence with Kaizen methodology can be achieved through several tools such as the Plan-Do-Check-Act, or PDCA, cycle, 5S methodology, and Root Cause Analysis, or RCA. These tools can also be used individually; however, when utilized within a Kaizen framework, such tools provide simple metrics to measure progress.

Plan-Do-Check-Act (PDCA) Cycle

When using the Kaizen methodology, the PDCA cycle is a practical tool to engage employees in identifying issues, testing improvements, and creating lasting change. The typical PDCA cycle has four steps.

- The first step is Plan, where the problem is identified, the goals are defined, and the plan of action is established.

- The second step is Do, where the plan is executed, and the changes identified during RCA are implemented.

- The third step is Check, where the implementation results are evaluated, and the actual results are compared to the desired outcome.

- The fourth and final step is Act. Based on the data and analysis from the Check step, action is taken to improve the process or implement a new solution.

5S Methodology

The 5S Methodology is a fundamental tool in Kaizen, and it stands for Sort, Set in Order, Shine, Standardize, and Sustain. It is often associated with the phrase “a place for everything, and everything in its place .” This concept applies to the bottom workforce in Kaizen methodology and moves upward through the organization.

- The Sort phase is the first phase of the 5S methodology. This phase involves the identification and elimination of waste while retaining the necessary items for an effective workplace.

- The Set in Order phase is the second phase of the 5S methodology. This phase aims to ensure that the required items are available and in the right amount throughout the workplace.

- The Shine phase is the third phase of the 5S methodology. This phase involves detecting and eliminating all unclean conditions and behaviors in a workplace.

- The Standardize phase is the fourth phase of the 5S methodology. This phase is carried out to effectively continue the improvements established in the first three phases.

- The Sustain phase is the fifth phase of the 5S methodology. This phase involves driving the organizational culture to maintain the momentum of the first four phases.

Root Cause Analysis (RCA)

When using the Kaizen method, Root Cause Analysis, or RCA, is a problem-solving tool that aims to identify the underlying causes of a problem or event. It involves a systematic approach of analyzing the problem, identifying the underlying causes, and developing solutions.

Some common techniques used in RCA include the fishbone diagram, the 5 Why analysis, the fault tree analysis, and the pareto analysis.

- The fishbone diagram, named for its fish-like shape, is a visual technique used in root cause analysis to identify the possible causes of a problem.

- The 5 Why analysis is a problem-solving technique used to identify the root cause of a problem. The analysis is performed by investigating and asking “why” for a certain problem and then asking “why” again for every answer that is received from the previous inquiry. This is typically repeated five times to ensure that all potential outcomes are covered.

- The fault tree analysis, which resembles an tree when drawn, is a deductive approach used to identify and analyze potential causes of system failures.

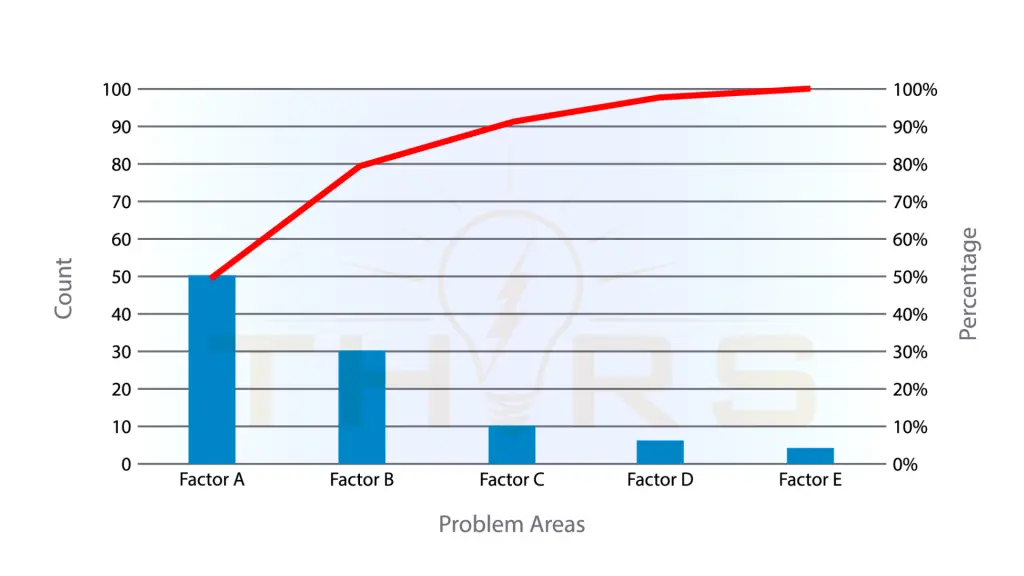

- The pareto analysis is a problem-solving technique based on the principle that 80% of the problems are caused by 20% of the causes. The pareto analysis can be applied to many aspects of manufacturing to pinpoint areas for improvement.

Integrating Kaizen methodology is potentially profitable for any company in modern manufacturing. However, Kaizen provides a variety of benefits in addition to profits. Implementing Kaizen methodology can also help organizations improve important areas such as safety, product quality, and company cohesion.

In our new course, Kaizen, THORS presents the crucial aspects of Kaizen for manufacturing in our visual and interactive learning format. In addition, we have a diverse manufacturing excellence library covering a variety of improvement methods used in manufacturing industries. Visit thors.com to expand the knowledge and skillsets of your workforce, and to ensure that your company has the highest quality training available today.