Casting Chronicles

The history of humanity is defined by man’s relationship with the material world. Man’s ability to make tools from metals has changed our historical trajectory.

A copper frog from Mesopotamia (modern-day Iraq) dating back to 3200 BCE is the oldest known casting. Farm tools made of cast iron were used in China in 600 BCE. In the Middle Ages, metal casting was widely used for making bells and artillery. Fast forward to the nineteenth century, iron and steel manufacturing underpinned the industrial revolution.

According to recent estimates published by the American Foundry Society (AFS), most people in the United States are rarely more than ten feet away from a metal casting: metal castings continue to permeate our lives in the Age of Plastic. Metal castings are indispensable to our engineering feats—automobiles, aerospace, construction equipment, machinery, house-hold appliances, medical devices, hardware, water industry, and other infrastructure. This year, in the United States, sales of metal castings will generate thirty-three billion dollars in revenue.

Casting: A Kaleidoscopic View

A casting is a metal part made by pouring molten metal into a mold, allowing it to solidify, and extracting the final casting. Metal castings are predominantly produced in sand molds. Sand molds are expendable, or single-use, molds that are destroyed after retrieving the casting.

Green sand is the most used molding medium; green sand is moist foundry-grade sand. Interestingly, green sand is not green in color.

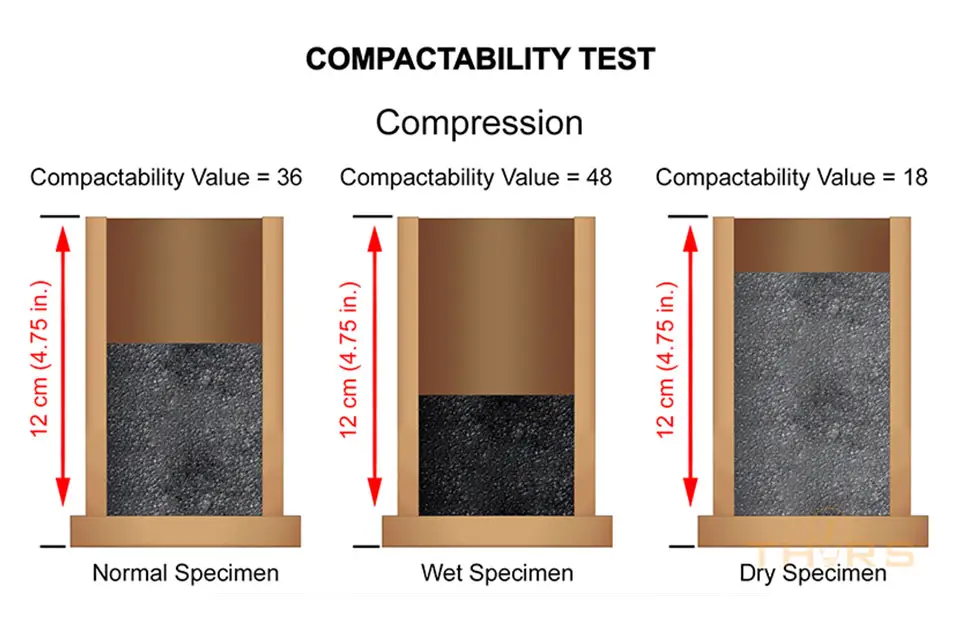

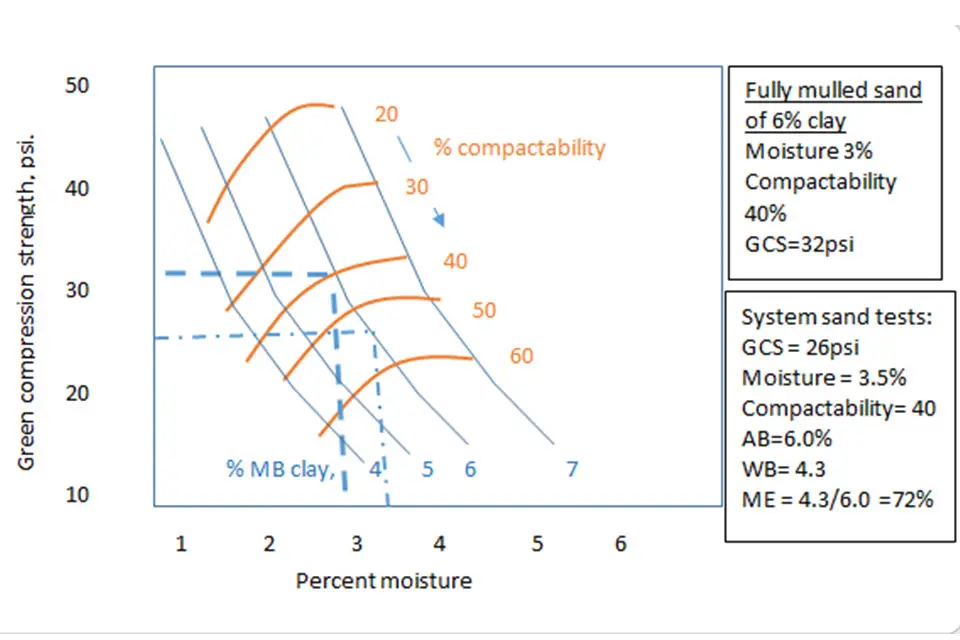

Green sand molds are made from three ingredients—sand, water, and clay binders. The molds are fabricated by compressing the sand mixture around the pattern. Ferrous metals including various types of iron and steel are primarily cast in green sand molds. Non-ferrous metals, such as aluminum, copper, bronze, magnesium, and zinc, can also be cast in green sand molds.

What makes casting in green sand molds a timeless technology?

- Versatile: green sand can be molded to produce complex castings with extensive gating systems.

- Tougher: Withstands high temperature; the molds retain their shape when the molten metal is poured

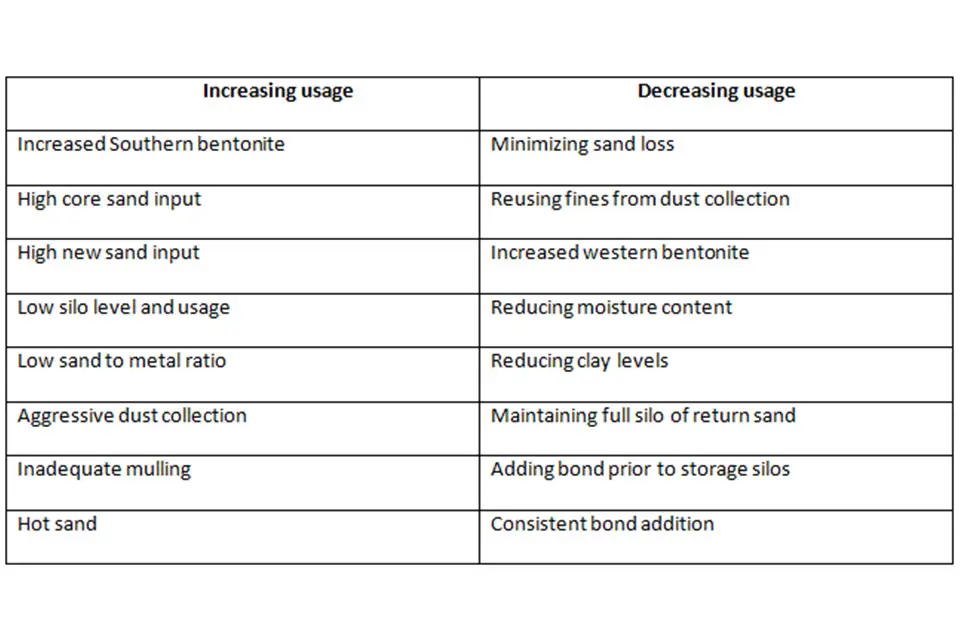

- Greener: casting with green sand is a sustainable process; the sand is recovered and reprocessed after every casting cycle and the metal scraps are recycled in an endless loop.

- Leaner: the abundance of sand makes the process cost-effective.

Sand casting is constantly evolving, the new wave in the field is 3D printing smart sand molds. Additive manufacturing or 3D printing of sand molds is in its infancy and promises great potential. By all indications, sand casting is here to stay!

Casting (De)coded

A sound casting begins with a flawless mold. Green sand mold production is a world of contrasts—Simple, yet sophisticated; Mundane, yet masterful.

At THORS eLearning Solutions, we create courses that encapsulate the rich lifetime experience of our experts and provide valuable insights on mold making and producing quality castings. We offer a suite of high-quality casting courses presented in a visually rich, interactive, and engaging fashion. THORS is a trusted training resource to maximize the potential of your workforce.