Introduction

Generating gear grinding is a precision machining process that is crucial in manufacturing, especially for producing gears. Gears are indispensable components of many machines and mechanisms, and their accuracy and quality significantly impact the overall performance and efficiency of the equipment. The generating gear grinding process meticulously removes small amounts of material from the surface of a gear using a threaded wheel, resulting in gears with more precise tooth profiles and smoother surface finishes. This article delves into the fascinating world of generating gear grinding, exploring the machine components, processes, benefits, and diverse applications.

Components

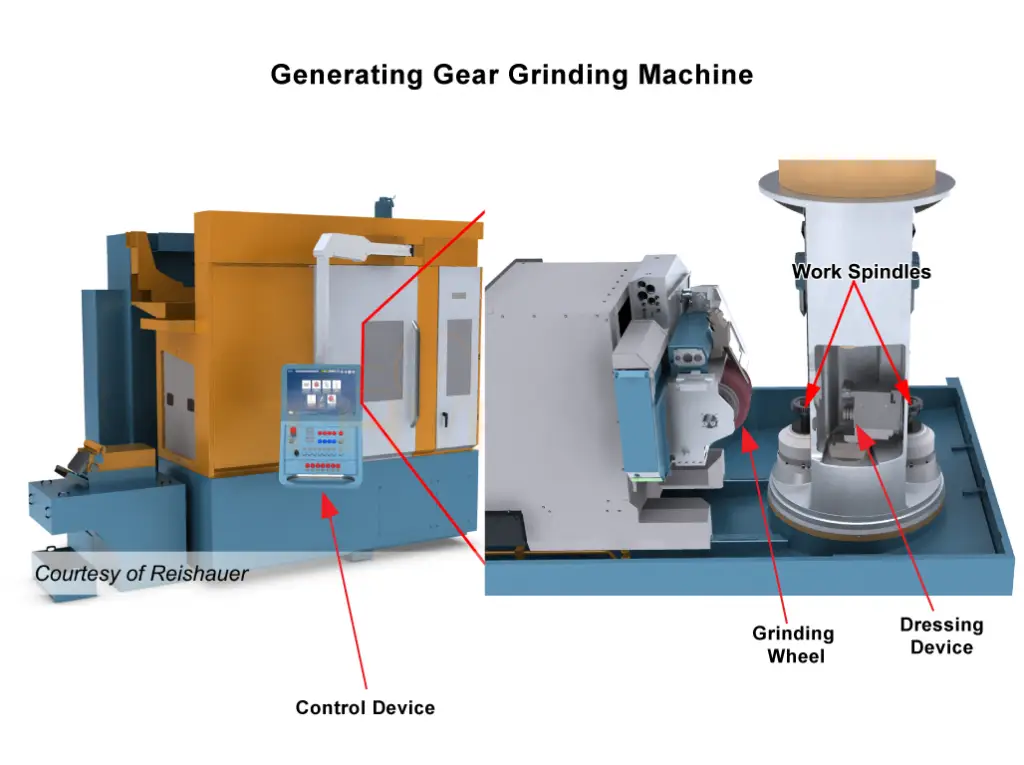

Gear grinding relies on specialized machinery to achieve precision and accuracy in the manufacturing process. A gear grinding machine is of several essential components.

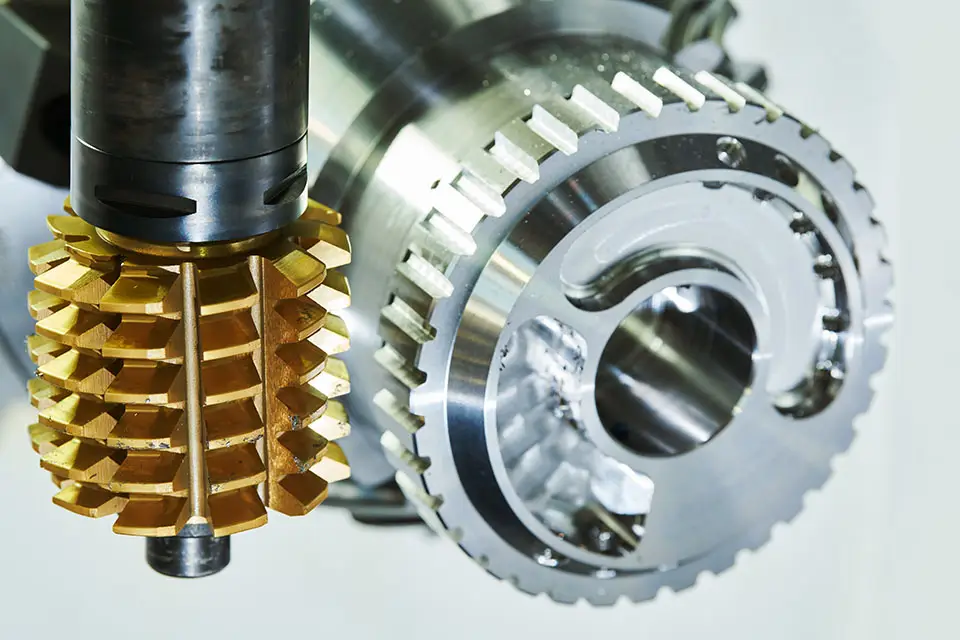

- The grinding wheel is the cutting tool used to remove material from the gear’s surface.

- The workpiece spindle holds the gear in place during the grinding process and rotates the gear at a controlled speed.

- The dressing device is used to shape the grinding wheel to the desired profile.

- The computerized control unit controls the machine’s movement and provides precise control over grinding parameters.

Gear Grinding Process

The gear grinding process involves several steps that are carefully controlled to ensure accuracy and efficiency. First, the gear is mounted on the workpiece and rotated at a controlled speed. The grinding wheel, which is shaped like a worm wheel, is then brought into contact with the gear teeth. The wheel rotates at a high speed and grinds away the material from the surface of the gear, creating the desired tooth geometry. The grinding process continues until the gear teeth have been fully ground as per requirements.

Benefits

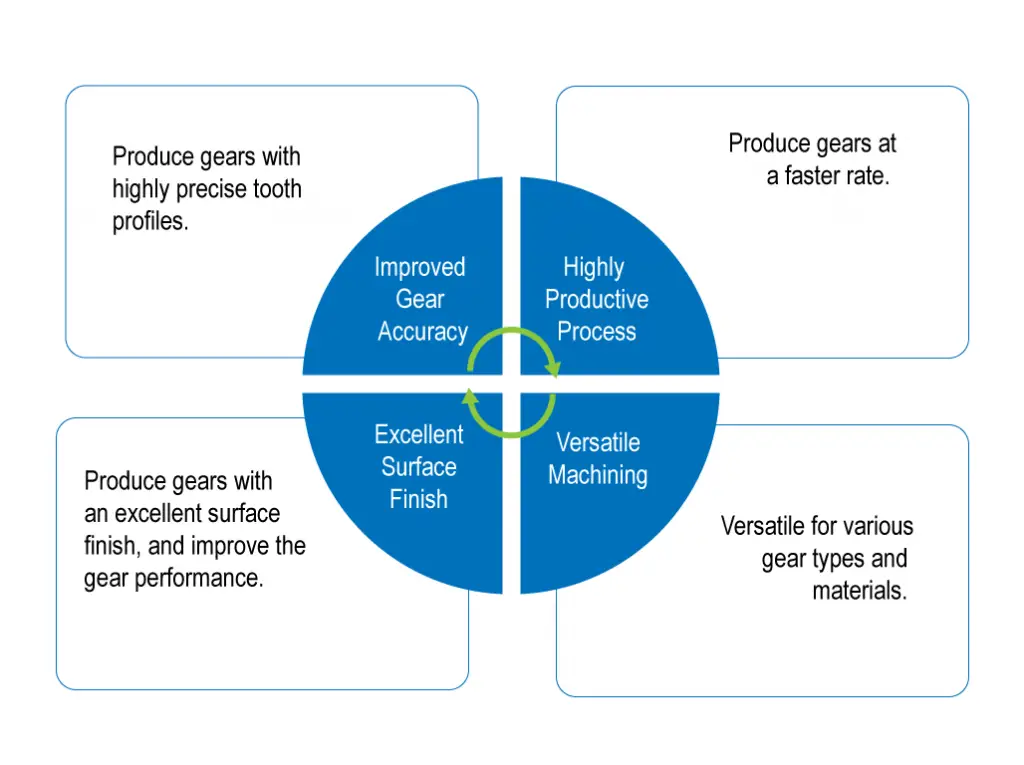

Some of the key benefits of generating gear grinding process:

Applications

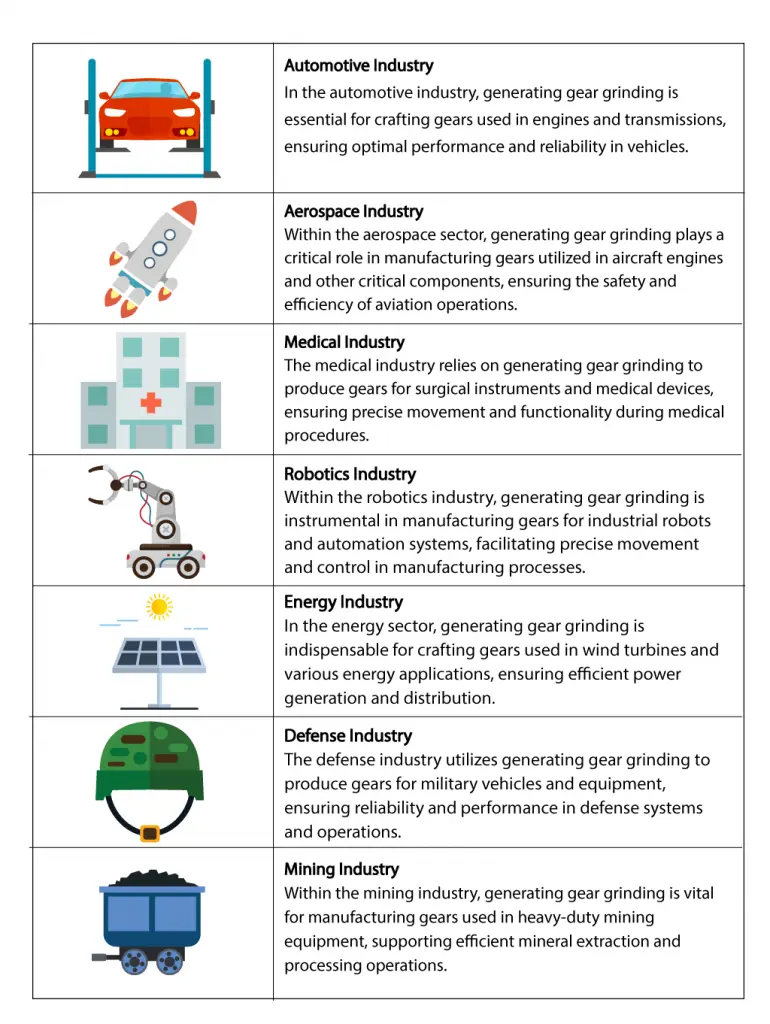

Let’s explore how generating gear grinding impacts various industries, ensuring precision and reliability in automotive, aerospace, medical, robotics, energy, defense, and mining applications.

Conclusion

The generating gear grinding stands as a pivotal method in precision manufacturing, accuracy and, versatility in crafting high gears with precise tooth profiles and smooth surface finishes. With ongoing technological advancements, generating gear grinding is positioned to evolve further, offering enhanced solutions for diverse gear applications across various sectors. These advancements pave the way for improved processes, reduced costs, and expanded capabilities, ensuring that generating gear grinding remains at the forefront of modern manufacturing solutions for years to come.