Geometric dimensioning and tolerancing is a complicated and complex standard that can lead to reading and interpreting errors. On drawings, GD&T is used as a point of reference in order to easily and effectively manufacture products that meet the fit, form, and function requirements of the part.

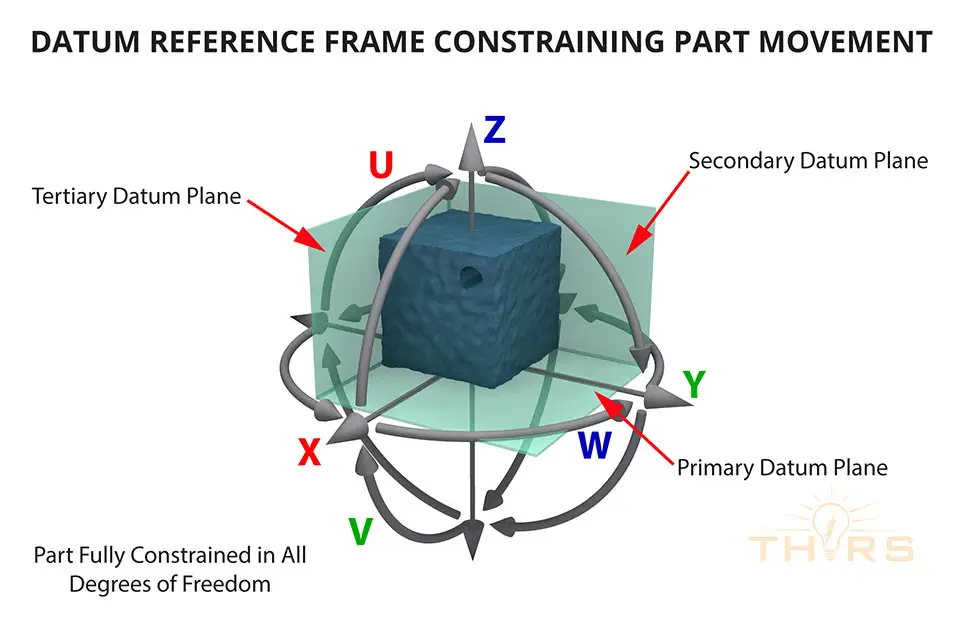

The above image shows a render of a datum reference frame fully constraining a part in all degrees of freedom.

Due to the complex nature of the standard, GD&T can be incredibly difficult for users to understand and interpret, potentially leading to a disconnect between the design, manufacture, and inspection of parts.

To better comprehend why GD&T is such a difficult concept, the following are common factors that can limit one’s understanding and interpretation of GD&T:

Prerequisite Knowledge

GD&T is an advanced-level concept that assumes the user has a full understanding of the rules, conventions, symbols, and associated terminology of print reading. Users who have not mastered the basic concepts found on a drawing are woefully unprepared to understand the complexity and technical intricacies of GD&T.

Language Fluency

In its simplest form, GD&T is a language comprised of symbols used on prints that offer an enhanced version of a drawing in order to clearly convey the design intent for the part. Thus, as a language, there are levels of fluency a user must acquire. Until a user is fully fluent in the language of GD&T, much like a native speaker in their mother tongue, they will not fully comprehend the dynamics and relationships between the part’s features expressed on a print.

2D vs. 3D Perspective

In addition to the prerequisite knowledge and levels of language fluency, a user must be able to mentally conceptualize the relationships expressed on a drawing between the features of a part. Individuals who are not familiar with print reading and how a two-dimensional drawing translates to a three-dimensional part will find GD&T incredibly difficult to navigate and elusive to grasp.

Due to the limitations imposed by the standard on the understanding and interpretation of GD&T, the following crucial areas in an organization could be affected:

- Bidding process

- Prototyping process

- Product quality

Bottom-line profitability can be drastically affected by issues in any one of these critical areas. However, organizations and individuals who dedicate themselves to mastering the basics of print reading, developing their GD&T language fluency, and shaping their 2D/3D perspective have the greatest potential for understanding this fundamental industry concept.

Kavita Krishnamurthy is an ASQ certified Six Sigma Black Belt with over 15 years of experience in the field of process improvement, manufacturing engineering, and quality management in the automotive and gear industries. She is also the subject matter expert of our GD&T Fundamentals course.