THORS recently heard from a customer using our Digital Checklist product for digitalizing JH (Jishu Hozen) manufacturing checklists. Find out more about their challenges prior to digitalization, and their successes afterwards in this use case study.

As one of India’s foremost manufacturers of transmission components, this Tier-1 supplier plays a crucial role in the two-wheeler supply chain. With decades of operational excellence, the company serves major OEMs through a network of multiple production plants across the country.

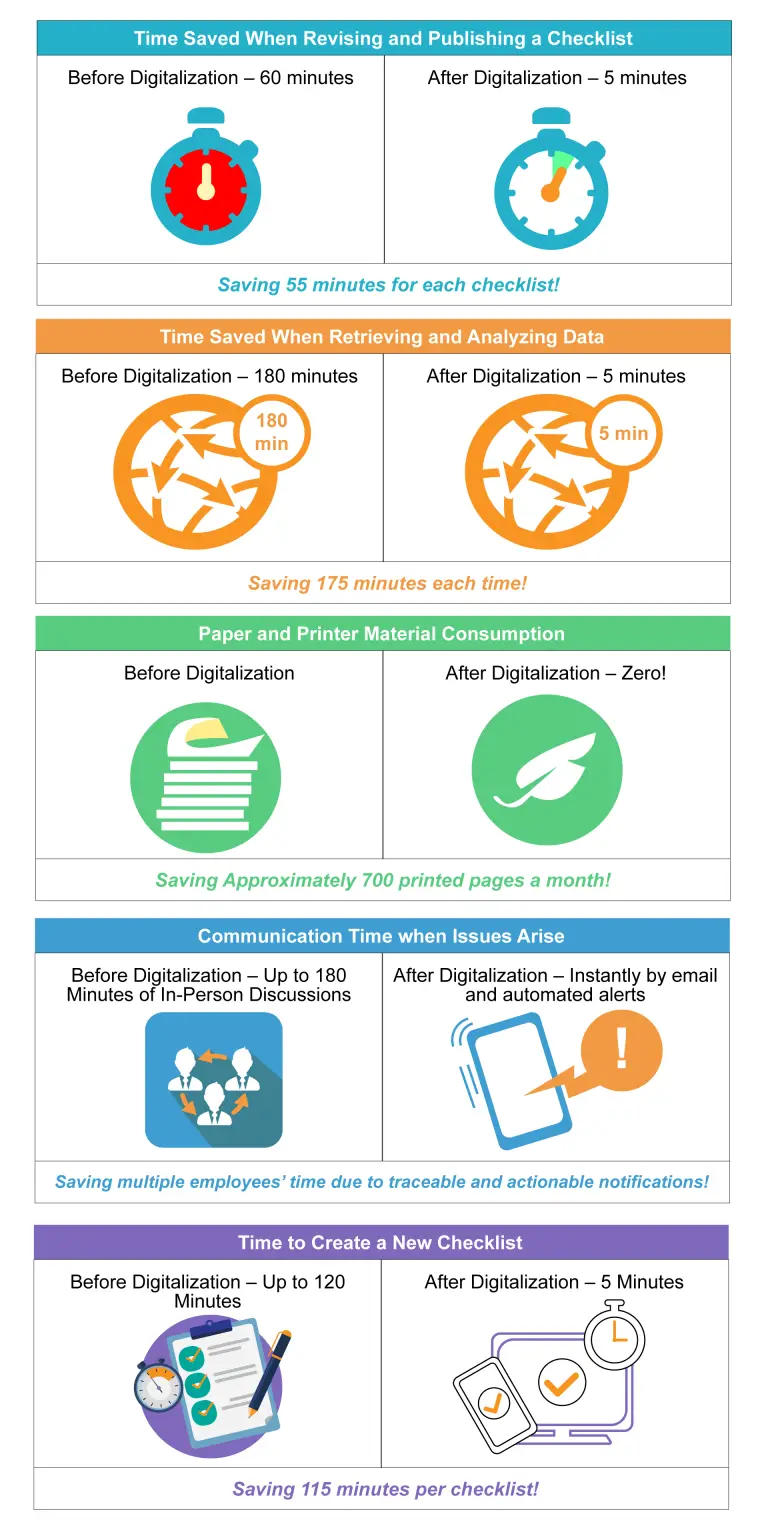

The organization follows Total Productive Maintenance (TPM) rigorously, with Jishu Hozen (JH) (a Japanese term that means Autonomous Maintenance) at its core. However, one area of concern had persisted across plants: the continued reliance on paper-based JH checklists, which posed several operational bottlenecks.

Challenges Before Digitalization

Inconsistent Execution:

Paper checklists were difficult to standardize across plants, leading to variability in execution and recordkeeping.

Data Inaccessibility:

No central visibility into abnormalities, pending tasks, or repeat issues.

Delayed Escalation:

Manual follow-ups delayed the closure of Non-Conformities (NCs).

Accountability Gaps:

Checklist mishandling and poor traceability limited plant-level ownership.

Mindset Resistance:

Teams were hesitant to shift from familiar paper processes to digital workflows.

Solution: THORS Digital Checklist

The corporate maintenance team led a multi-year transformation initiative to implement a Digital JH Checklist System across all plants using THORS Digital Checklist. The project roadmap was spread from 2023 to 2025.

Key implementations included:

- Tablet-based digital checklists at operator level

- QR-code initiated digital checklists at machines

- Plant-wise standardization of daily, weekly, and monthly items to be checked

- Integration of real-time issue logging and resolution tracking

- Escalation automation and reporting dashboards for leadership

“We never imagined paper-based checklists could be so limiting until we saw the full potential of digitalization. The Digital Checklist has turned routine inspections into a smart, traceable, and standardized system across our plants.”

— Corporate Maintenance Team

Results at a Glance

Value Additions & Feature Enhancements

The solution evolved through collaboration and customization. Major enhancements included:

- Checklist Standardization: Across plants with optimized checkpoints and multimodal instructions.

- Network Issue Handling: Offline alerts and recovery mechanisms to prevent data loss.

- Validation Logic: Prevented incorrect data entry and enforced TPM discipline.

- Issue Lifecycle Tracking: Each abnormality converted into a unique issue ID, tracked until actual closure of issue with date and time stamp.

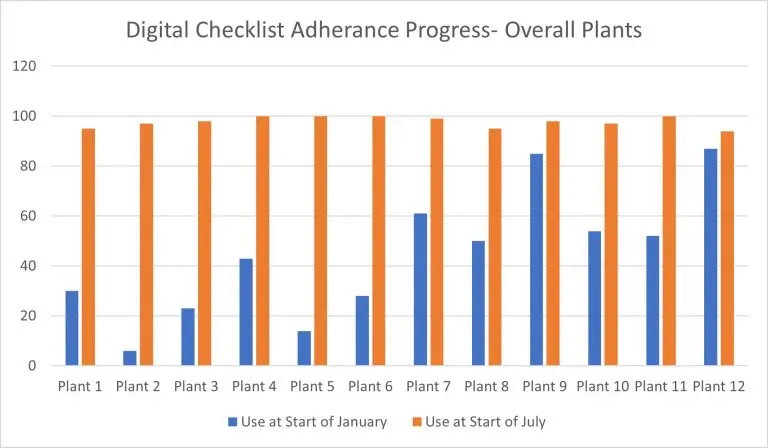

- Adherence Monitoring: SOPs, training programs, and scheduled reminders ensured high compliance.

- Advanced Reporting: Custom schedulers and alerts helped monitor pending actions at machine level.

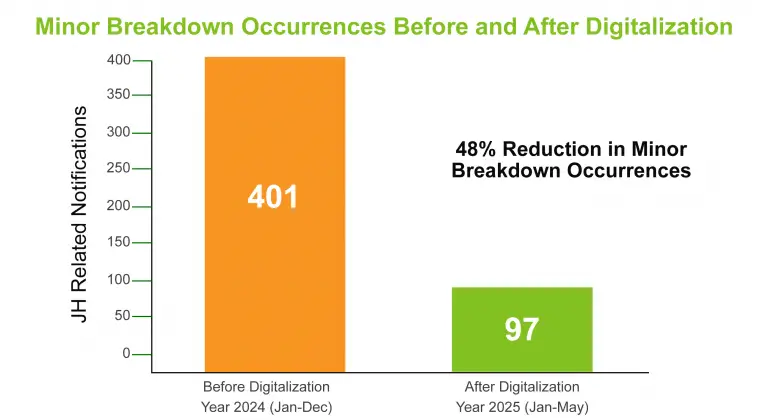

Operational Impact

| KPI (Key Performance Indicator) | Before Digitalization | After Digitalization |

|---|---|---|

| Minor breakdown visibility | Fragmented | Real-time, centralized |

| Non-conformity (NC) closure rate | Delayed | 100% with timestamp tracking |

| Execution adherence | ~60–70% (manual) | >95% (digitally monitored) |

| Plant-level standardization | Low | High across all facilities |

| Data access | Manual & delayed | Instant via dashboard |

Hurdles Overcome

- User Resistance: Frequent reminders, retraining, and SOP circulation helped overcome initial hesitation.

- Technology Compatibility: Selection of appropriate tablets, QR systems, and vendors ensured smooth deployment.

- Ownership Shift: Corporate maintenance temporarily took over checklist creation to ensure timely go-live across plants.

- Continuous Improvement: Over 23 system enhancements were developed during implementation to align the application to real-world plant conditions.

Conclusion

By implementing the THORS Digital Checklist solution, this leading Tier-1 transmission component supplier successfully digitalized the use of JH checklists across multiple plants. The transformation not only improved TPM adherence and audit readiness, but also reinforced a culture of operator ownership, visibility, and data-driven maintenance.

Want to find out more? Request a demo and a free trial!