Forging is one of the oldest and most reliable manufacturing processes, but it’s not without its challenges. Among them, safety stands out — not only in the forging operation but also in how the die is designed. Forging die design is not just about creating shapes; it’s also about ensuring safety for people, equipment, and the final product.

The link between forging die design and safety has been well documented for nearly a century. A 1927 report by the U.S. Department of Labor outlined common forging-related accidents and emphasized the need for better die setup, safety planning, and hazard prevention. In this blog, we explore the intersection between forging die design and workplace safety, and why modern engineers must pay attention to both.

1. Design Begins with Safety

Every forging die design decision has a safety implication. The flash land, draft angles, parting lines, and load paths influence the way metal flows and forces distribute. Poorly designed dies can:

- Cause misalignment and die failure

- Lead to part ejection or slippage

- Generate excessive force on presses and operators

By designing dies that encourage smooth flow and balanced loading, engineers can avoid sudden impact forces, part rejections, or dangerous rebounds.

2. Thermal and Mechanical Stresses Are Not Just Technical Concerns

Dies experience extreme cyclic loading and thermal shock, leading to fatigue, cracking, or catastrophic breakage. If such failure happens during production, it can put workers at serious risk.

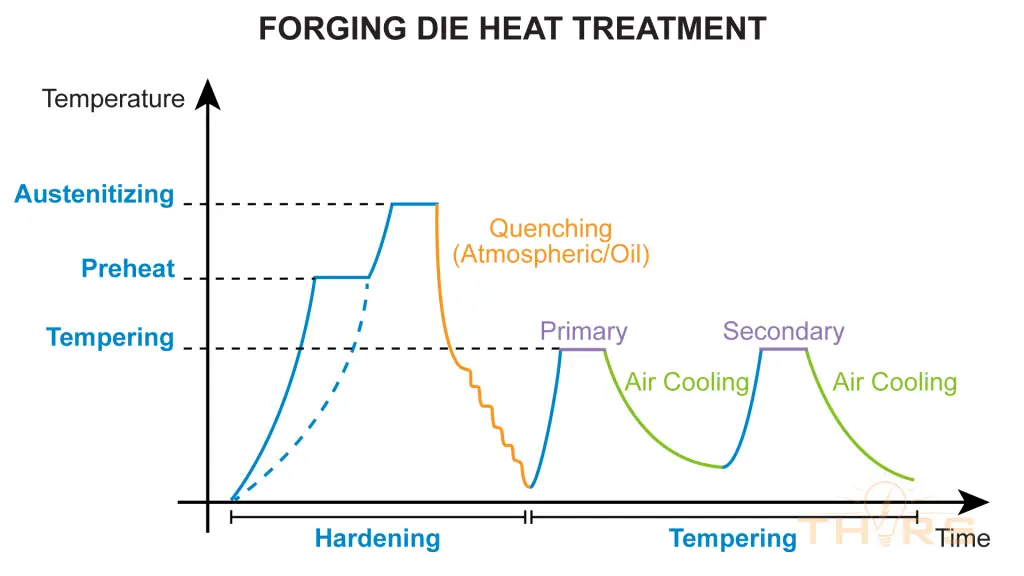

Design strategies that promote uniform temperature distribution, round off corners to reduce stress risers, and avoid excessive flash formation not only improve die life but also improve operator safety. Forging dies are also subjected to heat treatment processes to improve its hardness, toughness, and wear resistance.

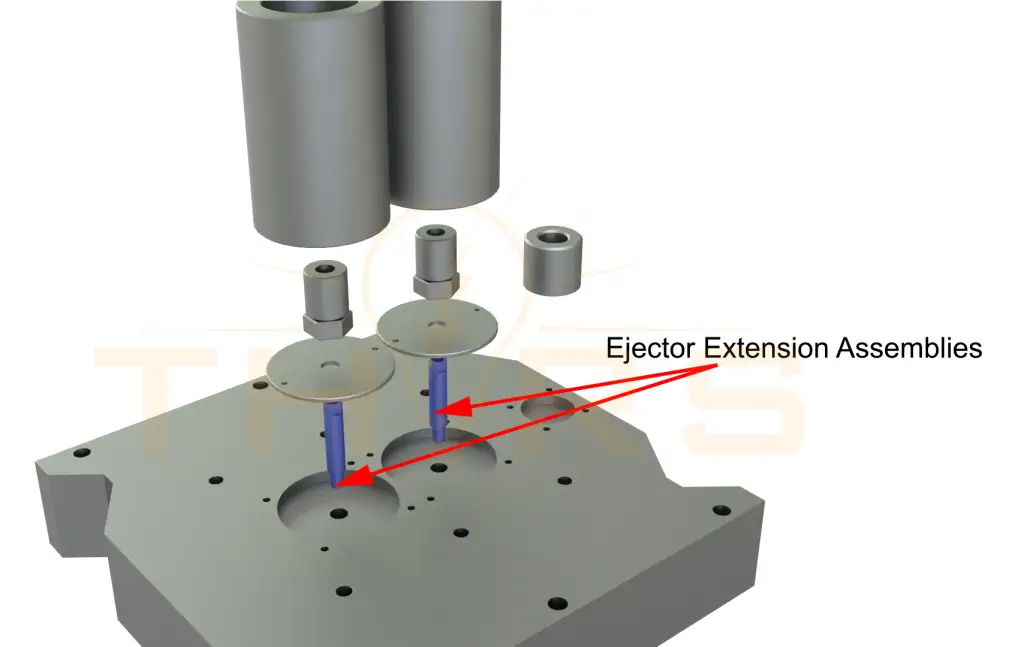

3. Ejection Systems Must Be Safe and Reliable

Forged parts are often ejected from dies under high pressure. A poor ejector extension assemblies or inadequate relief angles can cause:

- Part jamming

- Ejector pin failure

- Uncontrolled ejection

Forging die designers must integrate safe ejection mechanisms that allow smooth, predictable removal of parts without exposing operators to erratic part movement.

4. Ergonomics in Die Handling

Forging dies are large and heavy, and frequent die changes are part of shop floor life. Dies designed without proper lifting lugs, guides, or modular elements can be difficult and dangerous to handle.

Good die design facilitates safe mounting and dismounting, often with features like:

- Center-of-gravity markings

- Mechanical alignment aids

- Reduced weight through optimized cavities

5. Safety Considerations for Multi-Cavity or Multi-Stage Dies

When designing dies for progressive or multi-stage forging, synchronizing part flow between stations is essential. If one stage malfunctions, it could:

- Cause jams or crashes

- Create part buildup

- Lead to unexpected tool movement

Built-in fail-safe designs, sensors, and visual indicators can minimize risk during operation.

6. Forging Press Safety Relies on Die Design

A well-designed die:

- Prevents off-center loading on the press

- Reduces excessive tonnage usage

- Minimizes shock and vibration transferred to the machine

This improves machine health and keeps operators safe from mechanical failures, especially in high-tonnage hydraulic or mechanical presses.

7. Safety Labels, Documentation, and Best Practices

A forging die design is not complete until it is documented with proper usage guidelines, including:

- Max tonnage capacity

- Heating requirements

- Mounting orientation

- Lubrication or coating instructions

These help tool room and production teams use the dies correctly and safely.

8. Designing for Fail-Safe Conditions

In critical applications like aerospace or medical forging, die failure cannot be tolerated. Designers must incorporate redundancy, stress limits, and automated monitoring systems to reduce safety risks in case of unplanned load variations or part deviations.

Conclusion

Modern forging die designers are not just creators of metal shapes — they are gatekeepers of safety in the forging environment. A well-designed die can prevent countless incidents, reduce downtime, and increase worker confidence.

By understanding the safety implications of every design element, engineers contribute to a safer, smarter forging industry. The THORS’ course on Forging Die Design Essentials offers an in-depth exploration into understanding the foundational concepts of forging die tooling design and forging process control. Embrace this learning journey to master the art and science of forging die applications, a cornerstone of manufacturing excellence.