Course Description

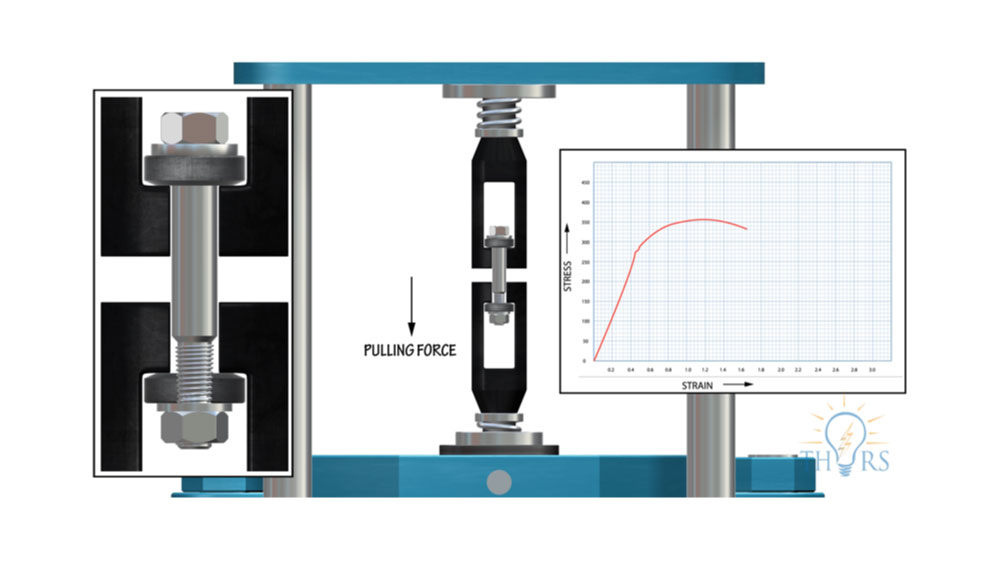

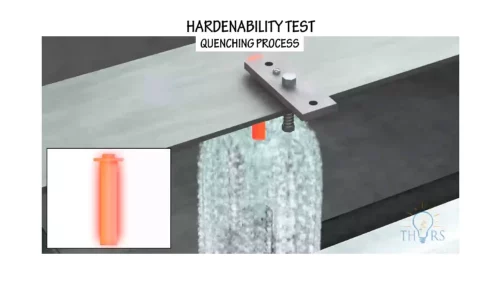

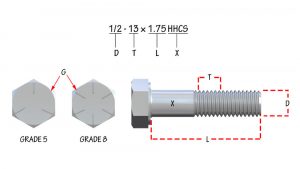

Fasteners: Threaded Fastener Testing and Defects introduces learners to both the mechanical properties of threaded fasteners and failure modes that might occur in service. The way in which threaded fasteners perform in service is the most crucial requirement for both manufacturers and purchasers of threaded fasteners, especially in safety-critical applications.

Who will benefit from this Threaded Fasteners Testing and Defects course?

Quality, manufacturing, engineering, purchasing, and sales functions at organizations that work with threaded fasteners. Students.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Fasteners: Threaded Fastener Testing and Defects

*upon successful completion

Related Posts

5 signs you should invest in effective workforce training

In today’s constantly changing marketplace, the importance of workforce training has never been greater. Workforce training has the ability to not only increase workforce efficiency

Knowing Customer’s Personality Style Adds Value

Maybe you think the value is obvious. If you can speak the same “language” as the person you are talking with, you can build trust

Comparing eLearning versus In-Person Learning

Introduction The world of education is rapidly changing, with technology playing an increasingly important role in the learning experience. One must take into account and