Course Description

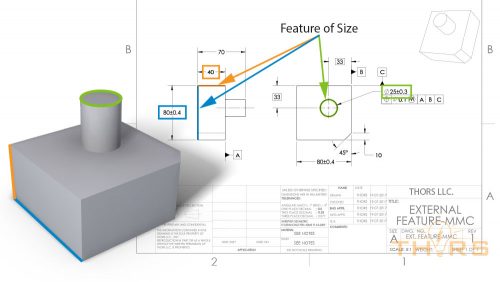

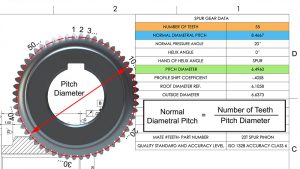

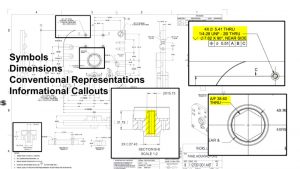

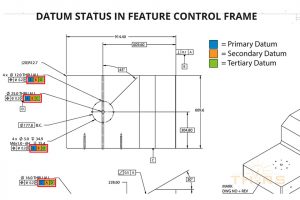

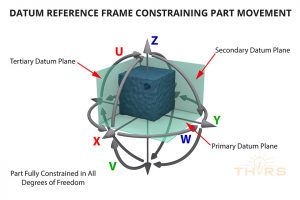

The GD&T Fundamentals course is an informative, advanced-level course introducing learners who have a thorough understanding of how to read and interpret engineering drawings to the fundamentals of geometric dimensioning and tolerancing (GD&T). In this course, learners are provided with an introduction to the key terminology used within the language of GD&T, the major symbols, the essential rules, and the datum systems used in GD&T. The concepts covered in this course are based on the ASME Y14.5: 2009 standard.

Who will benefit from this GD&T Fundamentals course?

Design, quality, mechanical, etc. engineers who are well versed with print reading.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for GD&T Fundamentals

*upon successful completion

Related Posts

Lack of GD&T Knowledge Can Impact Your Bidding Process

Read the first part of our GD&T Blog “3 Factors that Affect Understanding“. As a complex standard, geometric dimensioning and tolerancing can lead to reading

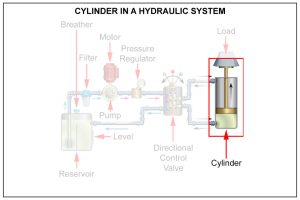

Understanding Engineering Drawings for Hydraulics

How are Engineering Drawings for Hydraulics Different from Regular Engineering Drawings? Engineering drawings have many symbols that are standard and carry over from industry to

GD&T: 3 Factors that Affect Understanding

Geometric dimensioning and tolerancing is a complicated and complex standard that can lead to reading and interpreting errors. On drawings, GD&T is used as a